Plate induction heating solution

Features:

Power available:100-8000KW

Available material:Steel,aluminum,copper

Heating method:Induction heating

Product Detail

Application Video

Product Tags

Induction heating has wide application in plate production process, such as plate heating for rolling, plate heat treatment. Forever can not only produce quality plate induction heating furnace but also our engineers can give the best plate induction heating solution.

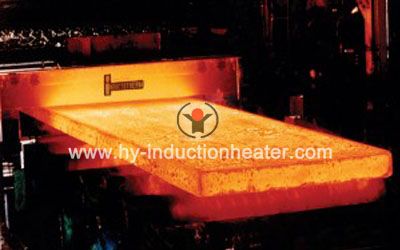

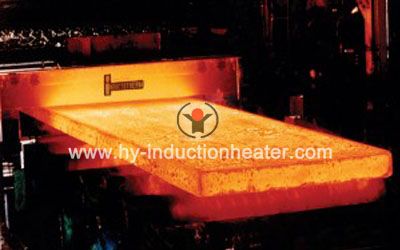

Induction heating steel plate before forging & rolling

Before a single plate,slab or sheet moves from the continuous caster to the forging press or rolling mill, it must be reheated.

Forever induction mass heating systems for plate,slab and sheet are used prior to forging or rolling operations. Temperature control and consistency are maintained from the surface to the core and over the length of the product. These compact heaters use the high efficiency power units.

Providing the rolling mill or forging press with a continuous supply of uniformly heated steel plate, slab and sheet at the proper temperature is crucial to efficient mill operations. Forever reheating systems include the world’s largest and most technically advanced induction reheaters, before rolling or forging.

Plate heat treatment: hardening, annealing,hardening & tempering

Steel plate induction hardening equipment features

- Increasing plate surface hardness, strength and wear resistance

- Deep case with tough core

- Parts may be tempered after induction hardening to adjust hardness level as desired

- Selective hardening process with no masking required

- Areas which require welding after heat treatment may be left soft

- Relatively minimal distortion

- Allows use of low carbon steels

- Can equipped with quenching machine

Steel plate hardening & tempering

Introduction about plate hardening and tempering

Hardening → Heating plate to a certain temperature.Cooling rapidly at water, oil, or other inorganic salts, organic aqueous solution etc. quenching medium. After quenching,steel work piece getting hard , but also brittle.

Tempering → In order to reduce steel plate brittleness, make the hardened heat preservation, a suitable temperature, higher than room temperature and lower than 710 ℃ , and then cooling.This process is called tempering.

Our steel plate induction heating equipment is all customized.So please let know the following information, then our experienced team will give you professional & cost effective solutions.

Steel plate width & length

Steel plate heating temperature

Steel plate production capacity

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)