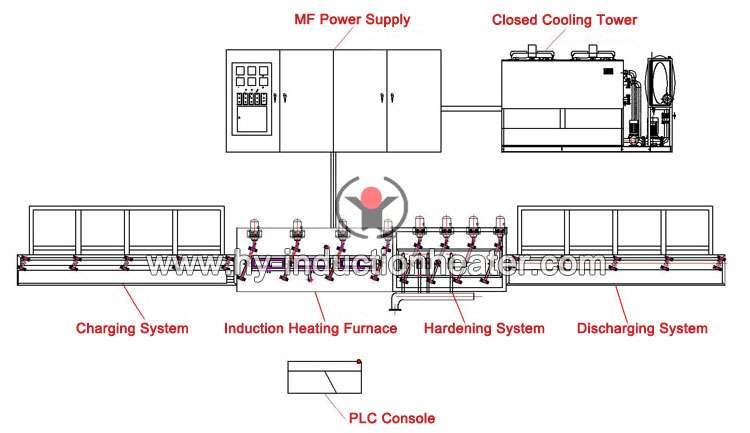

Steel pipe induction quenching production line

Features:

| Application | Steel pipe, pipeline, oil pipeline annealing and hardening |

| Power | 100KW-8000KW |

| Non standard | Professional customization |

| Temp.control | Infrared thermometer |

Product Detail

Application Video

Product Tags

Product Name:steel pipe induction quenching line

Typical application:

Forever steel pipe quenching line is available quenching or tempering for various material and sizes of pipe or tube.Your inquiry will have our great attention.

Steel pipe quenching production line features

● Power supply system: KGPS 160KW-1000KW/0.5-2.5KHz.

● Transmission roller table: The angle between roller axis and work piece axis is 18 ~ 21 °. The work piece is rotating and go forward at the uniform rate for uniform heating. Rollers between furnace are 304 non-magnetic stainless steel and water-cooled.

● Roller table group: Independent control for feeding group,inductor group and discharging group,which is beneficial to continuous heating to avoid work piece gap.

● Temperature closed-loop system: The hardening process adopts closed-loop control system which consists of America Raytek infrared thermometer and German Siemens S7 with high precision temperature control.

● IPC system: Powerful functions including the display of the current working parameters status, work piece parameters memory, storage, print, fault display and alarm and so on.

▲ Energy transformation : The power consumption is 280-320 KW/H.

Forever main pipe induction heating equipment: Steel pipe quenching line, pipeline hot spraying line, oil pipeline seam welding equipment, tube surface hardening system.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.