Steel ball production process

Features:

| Application | Making grinding ball,steel balls |

| Power | 100 KW-8000 KW |

| Heating method | Induction heating |

Product Detail

Application Video

Product Tags

Product Name: Steel ball production machine

Typical Application:

Forever steel ball production machine is specially designed for the grinding steel balls of different materials such as medium carbon steel, alloy steel etc, which is widely used in the field of mines, gold, copper, iron ore, aluminum ore, nonferrous non-ferrous metal ore, metallurgical and mining, cement, thermal power, coal water mixture, pellets, superfine powder, slag, fly ash, calcium carbonate, quartz sand etc industries grinding ball or rod miller and so on. Equipped with conveyor system and induction heating furnace, can realize mechanization and automation production,improving efficiency and reducing labor cost.

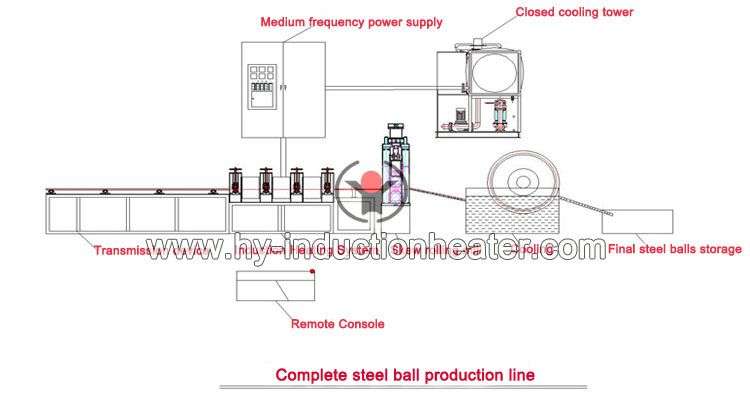

Steel ball production process layout

● Good and smooth surface and roundness.

● Equilibrium Internal and external hardness(<5HRC)

● Low broken rate, long working life

● High density, strong impact toughness

● High performance price ratio, cost saving is obvious

After-sales service

● Our company will send professional and experienced engineer to go to customer’s plant to install and debug the steel ball production line.

● 12 months quality guarantee period, long term technical service and spare parts support.

● Give response within 24 hour after receiving customer’s email or call.

● Along with equipment, we will provide whole technical documents and spare parts list.

Manufacturer & supplier of induction heating equipment for bars, rods, billet, pipe, slab, plate.Welcome to contact us for quotation or other information.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.