Short bar hardening and tempering production line

Features:

| Material | Carbon steel, alloy steel |

| Suitable for | Threaded bar, sucker rod,short bars etc. |

| Process | Hardening and tempering |

Product Detail

Application Video

Product Tags

According to the particularity of heating, the short bar hardening and tempering production line adopts continuous heating mode to meet the heating process requirements. The short bar hardening and tempering production line regulates the temperature through power regulation, and the mechanical transmission part is driven by a speed-regulating motor, which can adjust the speed and power of the workpiece.

Basic information for short bar hardening and tempering production line

| Material | Carbon steel, alloy steel |

| Suitable for | Threaded bar, sucker rod,short bars etc. |

| Efficiency | Customized |

| Process | Hardening and tempering |

Short bar hardening and tempering production line production is highly automated:

1. We can provide a full set of short bar hardening and tempering production line, including automatic feeding system, transmission system, quenching system, cooling system, tempering system, automatic discharging system, IGBT power supply and PLC whole process control.

2.The transmission speed is adjustable, so our short bar hardening and tempering production line can meet different customer requirements for production speed.

3.In order to ensure the stability of product quality, we strictly control the entire processing temperature using high-precision and non-contact infrared thermometer.

4. For the tension monitoring and control device of short bar hardening and tempering production line, induction heat treating can be performed under constant micro tension.

5. Our PLC system can record and save all process parameters of induction quenching and tempering of workpieces. You can check the history.

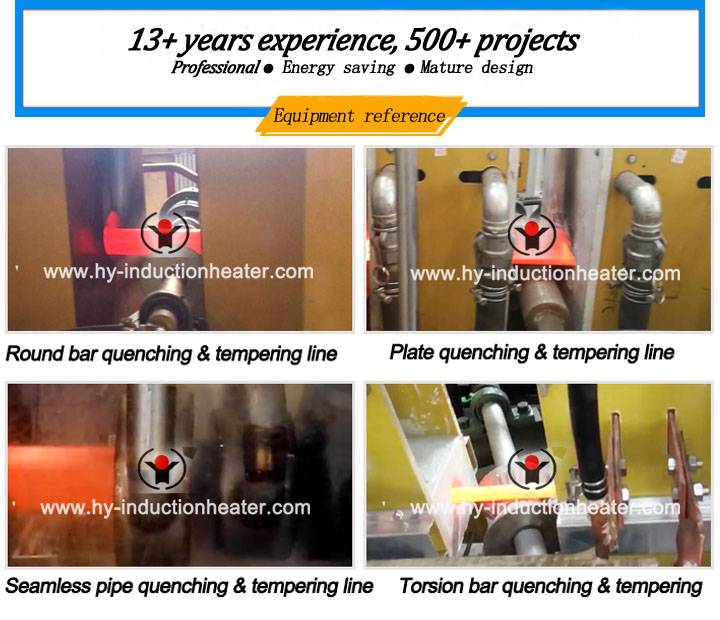

In the development process, Yuantuo has formed a unique brand of induction heat treating furnace: advanced independent research and development strength, advanced production technology, excellent after-sales service, high-end talent team, and scientific management structure, forming the market reputation of excellent quality and excellent service.

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(bar) | PLC Control | IGBT200KW Hardening |

| Ø30-Ø70mm( bar) | PLC Control | KGPS350KW Hardening |

| Ø80-Ø110( bar) | PLC Control | KGPS450KW Hardening |

| Ø16-Ø32 mm(rod) | PLC Control | IGBT200KW Hardening |

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.