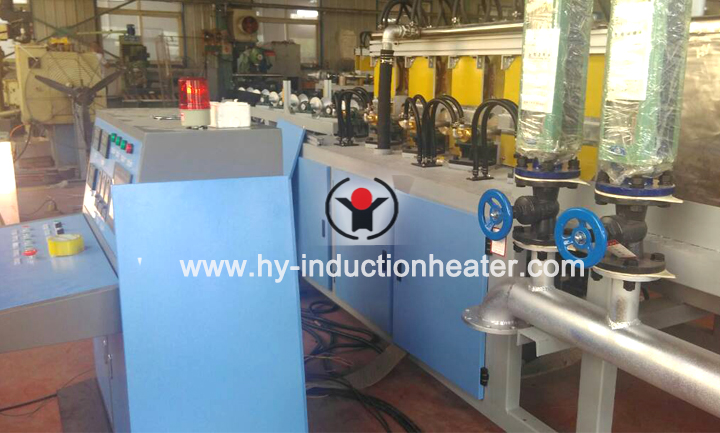

Shaft heat treatment line

Features:

● Uniform heating & cooling

● PLC control system

● Heat treating for shaft, torsion bar, stabilizer bar, grinding rod, sucker rod, pipe, plate

Product Detail

Application Video

Product Tags

● Shaft diameter: ø20-150mm

● Shaft length: 800mm-2000mm

● Power required: 100-2000KW The specific power depends on the specific shaft production capacity.

● Induction heat treating process: Quenching, tempering or annealing

Shaft heat treatment line composition

● Storage platform

● Automatic feeder

● Conveying roller table, the rollers are makde of stainless steel.

● Induction heater for quenching and tempering

● Spray water cooling device

● Cooling table

● Bar receiving platform

● Induction heating power supply

Optional part:

● Infrared thermometer

● Transformer

● Cooling machine

Shaft heat treatment line advantages

● Shaft heat treatment line is using PLC fully automatic control system to control all the actions including feeding, heating, cooling and discharging to save labors.

● The roller table of ribbed Shaft heat treatment line adopts 304 non-magnetic stainless steel, roller shaft and the workpiece into the 18-21 degree angle. The workpiece will go forward while rotate by itself.

● The feeding system of Shaft heat treatment line is using Nordisk reducer with independent inverter control.

● The Shaft heat treatment line is using automatic injecting system to maintain the service life of components.

● Input system pneumatic components adopts well-known brands such as: cylinder, diad, controller and so on.

● The temperature fluctuation range is ± 10 ℃ with uniform heating. The operator can see the temperature changes from the touch screen curve.

● After hardening and tempering, the shaft has very high toughness and impact strength.

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.