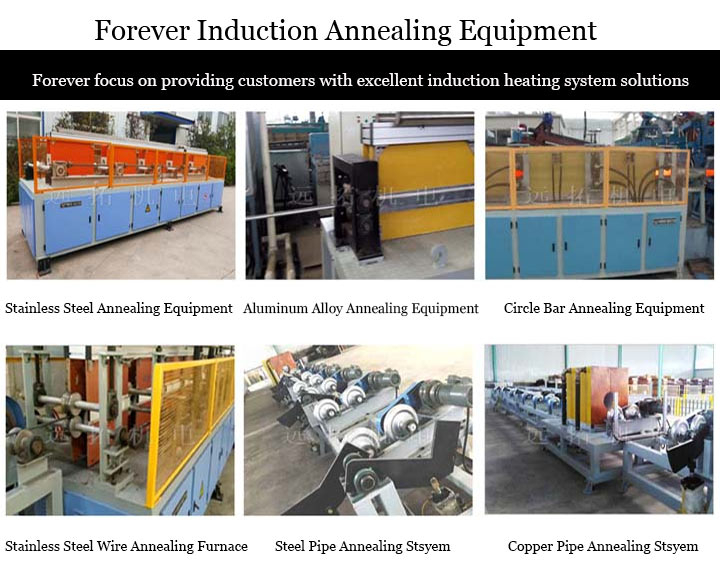

Pipeline induction annealing machine

Features:

Product Name: Pipeline Induction Annealing Equipment

Workpiece materials: Q195, Q235, 10, 20, 35, 45, 304316, 20Cr, 40Cr, 20CrHo, 35Crho, 42Crio, 40CrNIMOGCr15, 651m, 50Mm, 50cr, 3Cr2w8v, 20CrhmTi, 5Crhmio, etc. Workpiece diameter range: diameter above 20mm

Workpiece length range: greater than 2m

Intelligent intermediate frequency power supply series: KGPS160KW-8000kW

Product Detail

Application Video

Product Tags

Features:

Product Name: Pipeline induction annealing machine

Workpiece materials: Q195, Q235, 10, 20, 35, 45, 304316, 20Cr, 40Cr, 20crmo, 35Cro, 42CxIo, 40CrNIMO, GCr15, 651m, 50mm, 50Cr, 3cr2w8y, 20CrhmTi, 5CrMnMo, etc. Workpiece diameter range: diameter above 20mm

Workpiece length range: greater than 2m

Intelligent intermediate frequency power supply series: KGPS160KW-8000kW

Power consumption: calculated based on the customer’s workpiece material and diameter, heating temperature, operating speed, etc.

The Pipeline induction annealing equipment adopts an intelligent induction heating power supply control, which has the following characteristics:

Parallel resonance design, phase shift power regulation, mature and stable intermediate frequency annealing equipment; It has more advantages in the high-power range of 3000KW and above, with DSP control and high-speed capture phase-locked start, meeting frequent start stop requirements and a high success rate.

Variable frequency load adaptation, frequency adaptation range 200-10000Hz, automatic matching for induction furnace replacement, no need for manual adjustment.

Contact person: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)