Pipe induction hardening machine

Features:

| Material | Carbon steel, alloy steel |

| Convey mode | Roller table |

| Control system | Closed-loop temperature control |

Product Detail

Application Video

Product Tags

Forever pipe induction hardening machine is suitable for various kinds of pipe hardening heat treatment. Equipped with intelligent IGBT power supply, our pipe induction hardening machine is available for wide range of pipe diameter. Familiar with pipe induction hardening process, we can provide the most effective and energy saving proposals.

Basic information for pipe induction hardening machine

| Material | Carbon steel, alloy steel |

| Brand | Forever |

| Convey mode | Roller table |

| Power | 100-8000KW |

| Control system | Closed-loop temperature control |

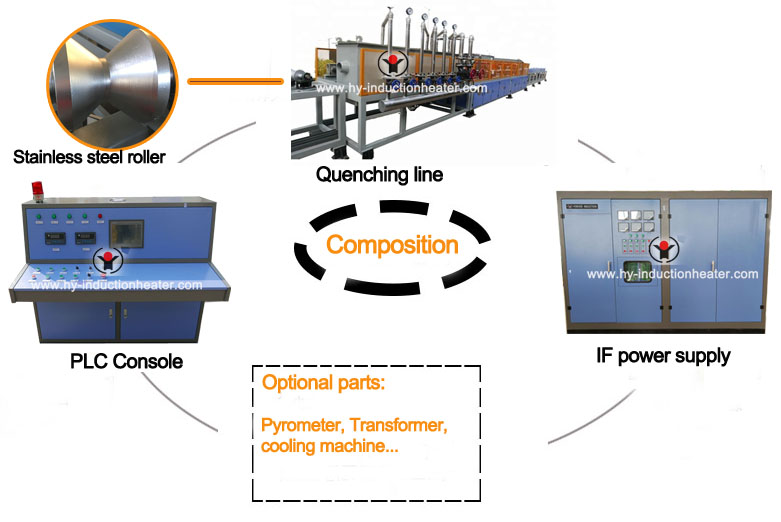

The pipe induction hardening system adopts PLC centralized control, which can be controlled manually or automatically. The control system is reasonable, stable, reliable and accurate, and the signal anti-interference ability is strong. At the same time, the system adopts an expansion module, and the collection temperature is closed-loop feedback signal, which is processed by the PLC program to make corresponding adjustments to achieve closed-loop control of the system.

Pipe induction hardening machine features:

1. Intelligent series resonant intermediate frequency power supply to ensure the consistency of product quality;

2.High strength base design, transmission mechanism has advantages of high accuracy and good stability.

3.Steel pipe induction hardening line adopts full closed-loop control for temperature.

4. Adopting imported frequency converter, the whole feedway is infinitely variable, high efficiency and energy saving; high production efficiency

5. The entire induction heat treating furnace system is completed independently, high reliability, anti-overload ability is strong.

Steel pipe induction hardening line control system adopts PLC automatic control with industrial touch screen or industrial computer. Siemens PLC is in a separate control cabinet, which can provide all the process control of the mechanical action and the actual state of the heating power, all operating conditions, operation modes, time control of the movement signal and control & record of all process data from the beginning of the operation of the equipment. According to different countries and regions to provide the appropriate language switch.

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.