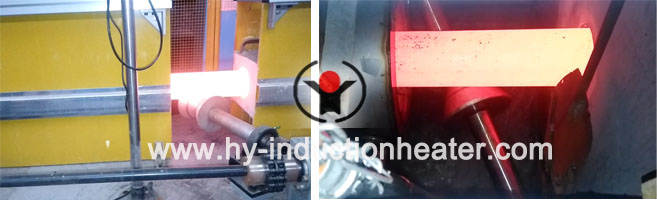

Medium frequency induction quenching equipment

Features:

| Material | 35CrMo, 20CrMnSiA, 45MnMoB, 45CrMo |

| Suitable for | steel bar, steel pipe, oil steel pipe, oil cylinder |

| Process | Quenching, surface quenching |

Product Detail

Application Video

Product Tags

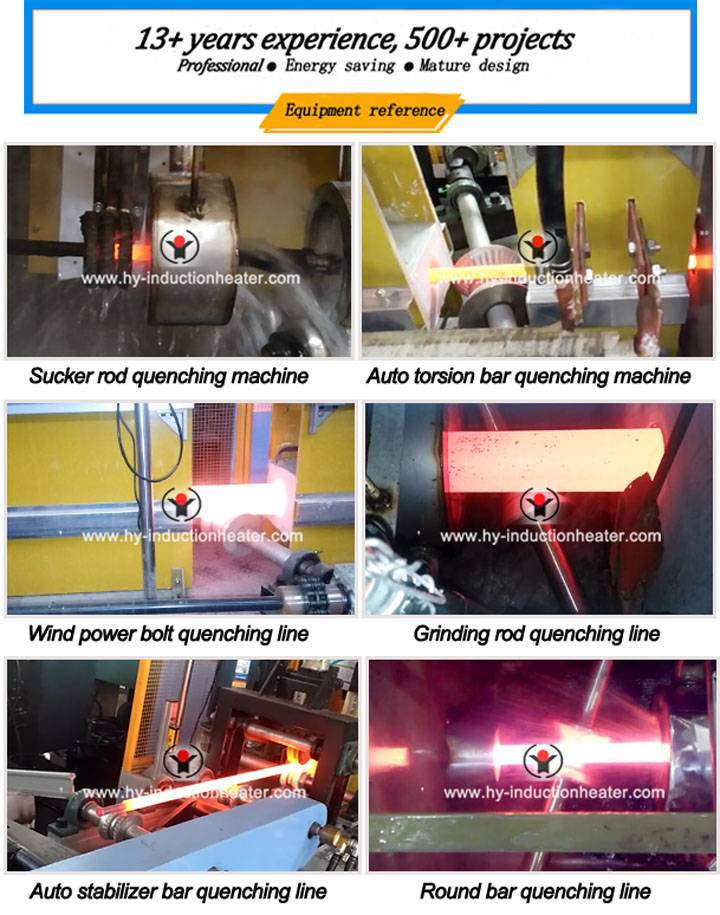

Adopting Siemens S7-300 PLC control system, Schneider button and light and PLC inverter, Forever medium frequency induction quenching equipment has been applied to sold bars and pipes, especially solid bars. So far, our medium frequency induction quenching equipment has successful case for torsion bar, grinding bar, stabilizer, shaft, wind power bolt, sucker rod and so on.

Basic information for medium frequency heat-treating equipment

| Material | 35CrMo, 20CrMnSiA, 45MnMoB, 45CrMo |

| Length | ≥2000mm |

| Suitable for | steel bar, steel pipe, oil steel pipe, oil cylinder |

| Efficiency | Customized |

| Process | Quenching, surface quenching |

Medium frequency induction quenching equipment features:

1. After the workpiece is quenched by the induction heat treating furnace, the workpiece will not be deformed due to the uniform heating and quenching during the quenching process.

2.The workpiece goes forward at uniform speed in the quenching process, so the heating is uniform. Before charging the water spray ring, we set infrared thermometer to measure the temperature. If the temperature is too high or too low, the system will automatically adjust it. The workpiece doesn’t need to be straightened after quenching heat treatment, which save invest for straightening machine.

3. After workpiece quenching, there is no crack phenomenon and the hardness has been increased.

4. Continuous inline feeding, heating and cooling makes the operation easier and convenient. Only one worker can operate the whole system.

Medium frequency induction quenching equipment advantage

1). Full power output

2). Equipment has features of easy operating, reliability, light weight, and no risk from high pressure.

3). Installation is simple, just need to connect power and power, a few minutes to complete.

4). Support 24 hours of continuous use, high efficiency and energy saving.

5). High induction heating speed, high efficiency and uniform heating, so there is no lack of welding and solder leakage.

6). Oxidation area is small, after welding, the bar is beautiful, firm and durable.

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(bar) | PLC Control | IGBT200KW Hardening |

| Ø30-Ø70mm( bar) | PLC Control | KGPS350KW Hardening |

| Ø80-Ø110( bar) | PLC Control | KGPS450KW Hardening |

| Ø16-Ø32 mm(rod) | PLC Control | IGBT200KW Hardening |

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.