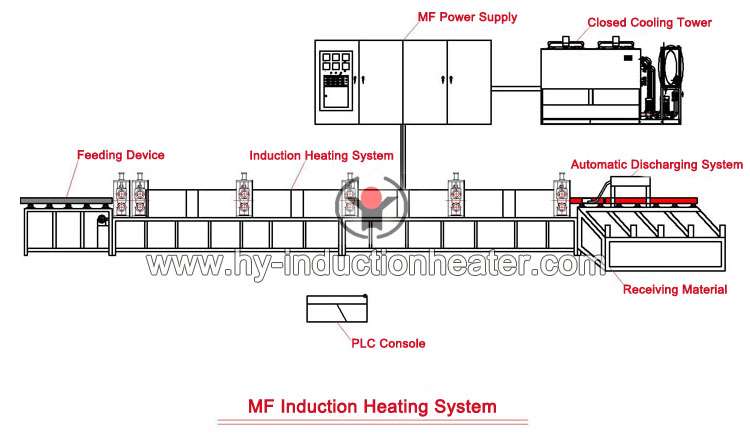

Medium frequency heating equipment

Features:

| Application | Heating, reheating, preheating, forging, rolling, extrusion, hardening |

| Power | 100 KW-10000 KW |

| Non standard |

Professional Customization |

Product Detail

Application Video

Product Tags

Product Name: Medium frequency heating equipment

Typical Application:

Heating before forging: Used in gear, ring gear, axle connecting rod, bearing, shackle, rigging and other products heating before forging process;

Online heating: Pipeline anti-corrosion coating, steel (wire) pipe online tempering process,steel billet online heating;

Local heating: U type bolt bending, hot roller assembly, steel pipe bending and other production heating process;

Diathermy and reheating for bars, round bars, square steel and steel slab.

Metal material online forging, such as precision forging of spur gear, axle connecting rod and bearing, extrusion, hot rolling, quenching and tempering, annealing, tempering.

Characters and Advantages of Medium frequency heating equipment

● High control accuracy of work piece length, speed, and temperature.

● Good heating uniformity of work piece, small temperature difference between core and surface, high control accuracy.

● Special energy conservation optimal design, low energy consumption, high heating efficiency, lower cost than coal furnace.

● Integration design of inductor and furnace body, quick-change connector for different inductors, easy to change and replace.

● Fit environmental protection requirement standard,no pollution, and reduce labor intensity of workers.

Forever- Induction heat treating equipment can be designed and produced according to your work piece size, shape and heating equipment.For more details, please refer to our website【http://www.hy-inductionheater.com/】

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.