long bar hardening and tempering production line

Features:

| Material | Carbon steel, alloy steel |

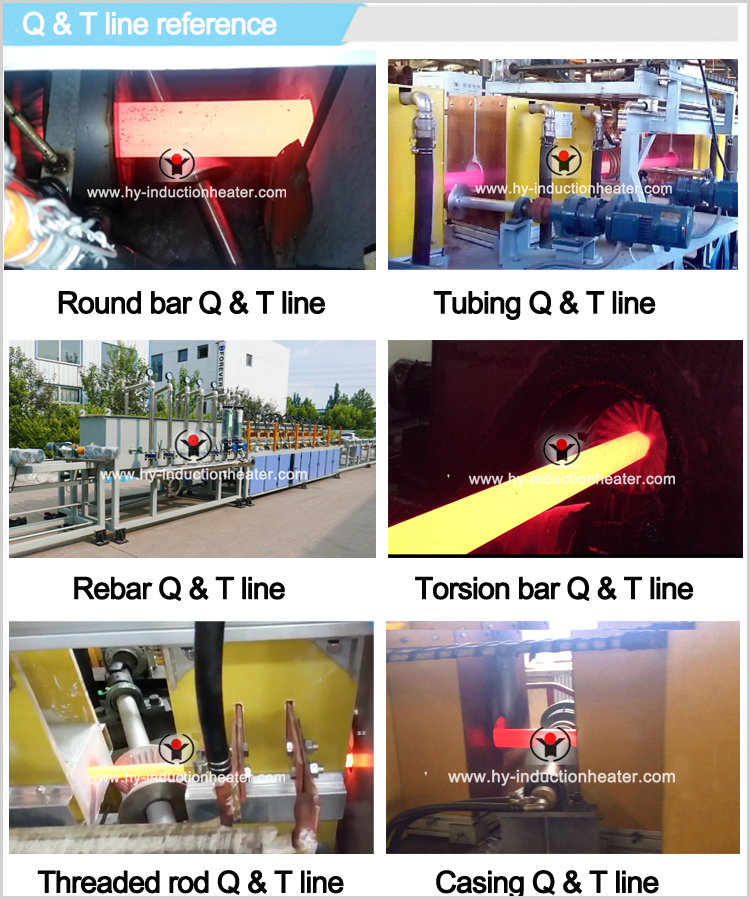

| Suitable for | Long bars,long pipes |

| Process | Hardening and tempering |

Product Detail

Application Video

Product Tags

Forever long bar hardening and tempering production line has advantages of reliable performance, no deformation, no crack, uniform hardness and so on. Over 13 years development for the hardening and tempering furnace, Forever has rich experience for the process of long bar hardening and tempering.

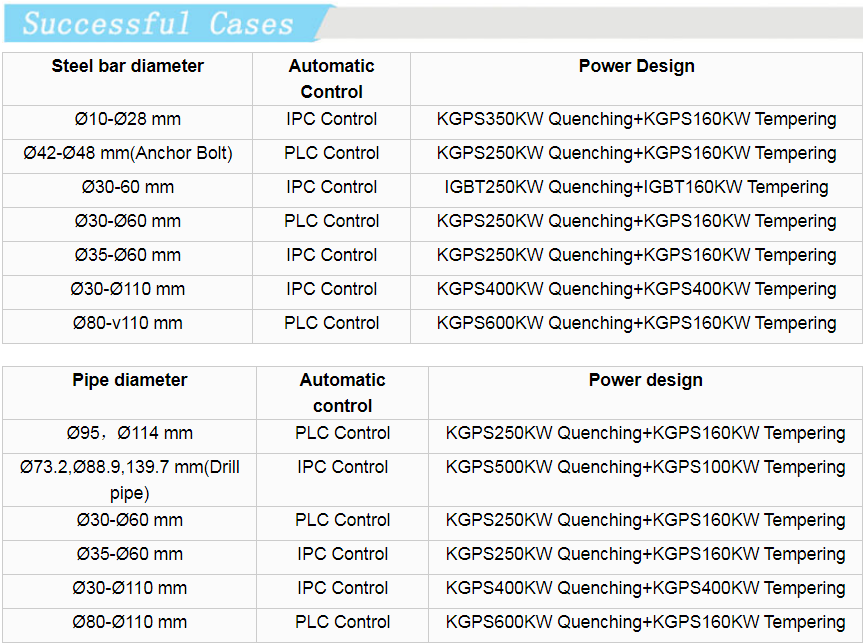

Process parameters of long bar hardening and tempering production line:

● Workpiece material: Q195, Q235, 10#, 20#, 35#, 45#, 304, 316, 20Cr, 40Cr, 20CrMo, 35CrMo, 42CrMo.

● The diameter range of the workpiece: diameter 10mm ~ 150mm

Length of the workpiece: above 2m

● Intelligent quenching intermediate frequency power supply power range: KGPS160KW-1000KW

Intelligent tempering medium frequency power supply range: KGPS100KW-600KW

● Power consumption: calculated according to the material and diameter of the workpiece, heating temperature and the speed of operation.

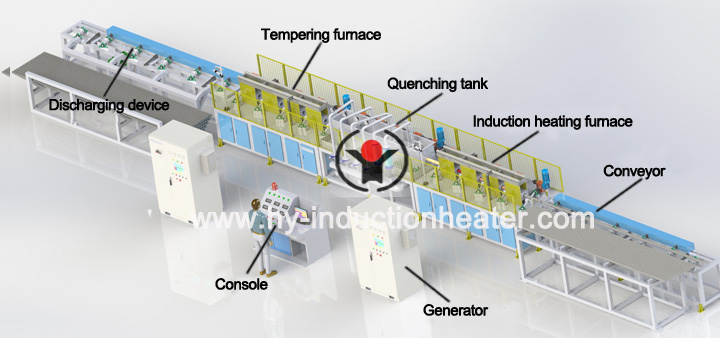

Main configuration for long bar hardening and tempering production line:

1. Intelligentized IF power supply for quenching (control system for long bar quenching)

2.Intelligent IF power supply for tempering (control system for long bar tempering)

3. Induction heating coils for quenching and tempering.

4. Resonant capacitors and furnace cabinets (including stainless steel pipes)

5.Quenching tank (including stainless steel sprinkler ring, flowmeter and conveyor roller table)

6.Connection cable from IF power supply to the capacitor.

7. The input and output rollers of the long bar hardening and tempering production line (Long bar will rotate and go forward to get uniform heating and cooling).

8. Quenching and tempering infrared thermometer (equipped with the infrared thermometer of the United States to display the temperature of long bar in real time).

9.Central control console (including variable frequency speed control and temperature control, touch screen, remote start and so on).Its function is the whole control for long bar hardening and tempering production line directly on the central console operation, only 1 worker can operate the whole set of hardening and tempering furnace, saving manual cost.

The characteristic of the long bar hardening and tempering production line:

1.The heating speed is fast, and the oxidation decarbonization is less: because the principle of medium frequency induction heating is electromagnetic induction, the heat is produced in the workpiece itself. Because the heating mode is fast, the oxidation is very little, the heating efficiency is high, and the process repeatability is good.

2. Automatic loading, heating, cooling, conveying and discharging save the manual cost and ensure the consistency of long bar quality.

3.Uniform heating, high temperature control accuracy: induction heating is easy to achieve uniform heating, and the core temperature difference is small.

4. Low energy consumption and no pollution of long bar hardening and tempering production line: induction heating has high heating efficiency, low energy consumption and no pollution compared with other heating methods.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction billet heater in China; Glad to be your business partner in induction heating field.