Aluminium bar induction heating furnace

Features:

Application: Forging , Forging , Rolling & Quenching

Material: Carbon steel, Brass,Iron,Alloy steel,Stainless steel,Aluminum

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product name: Aluminium bar heating furnace

Forever is a leading producer of high-quality rod induction heating machine and solutions for the bar or pipe heat treatment using world-class remelt technology. We are dedicated to providing our customers with superior induction heating rod furnace and unmatched service in the industry.

● Rod type: Thread rod, sucker rod, torsion rod, drill rod, rebars

● Rod material: Carbon steel, Aluminum, Copper

● Heating way: induction heating

● Rod diameter: 20-300 mm

Applications for Aluminium bar induction heating furnace

- Forging & forming: Suitable for rod, pipe, plate, slab, billet, auto parts, fasteners

- Surface quenching: Suitable for Shaft, long bar, long pipe, sucker rod, drill pipe, drill rod

- Annealing: Suitable for Tube, pipe, pipeline, copper pipe

- Hardening & tempering: Suitable for Drill pipe, drill rod, piston rod, bolt, shaft

- Special application: Bar heating used for forging steel balls, rolling steel balls.

Benefits for induction heating furnace

- High -efficiency solid-state power units

- Standard units available in frequencies between 60 Hz and 10000 Hz

- Dual frequencies available for pre and post Curie heating

- Modular design for quick coil change to accommodate for different sizes

- Level control to centralize all bar sizes in coil opening

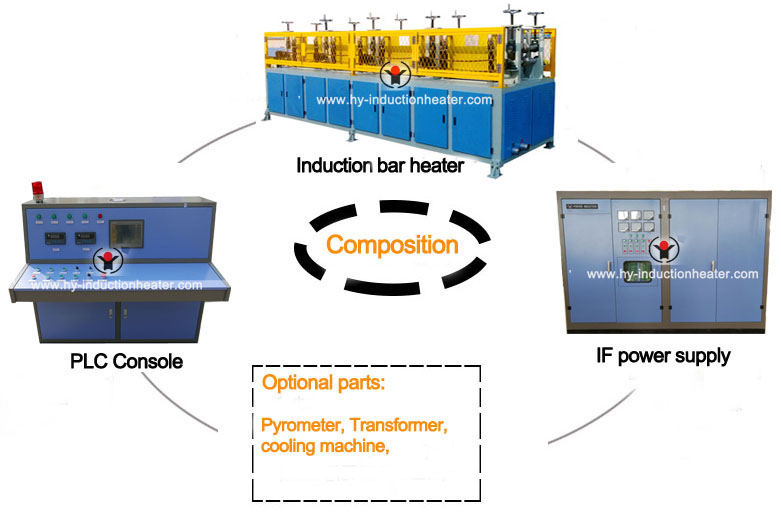

- Fully automated, PLC controlled material handing system

Characteristics of rod induction heating machine :

1. The induction heating technology used in the rod induction heating furnace not only has less environmental pollution and high production efficiency, but also has a lower cost than gas heating.Equipped with pyrometer in the exit of the heater, you can monitor and control the heating temperature for the whole process.

2. The machine is non-standard product, so the induction coil should be designed according to the customer’s production requirement.

3. The induction heating equipment designed by us can meet your requirements by adjusting the size of the inductor according to the bending degree of your steel.

4. Control system: PLC automatic control is realized in the whole heating process of the furnace, and production records such as heating quantity are displayed timely. This console is used alone, and the furnace has a customized man-machine interface, highly humanized operation instructions, full digital, high-depth adjustable parameters.

| Bar Diameter | Bar Length | Heating Temp. | Production capacity |

| Φ36-45mm | 1500mm | 1125°C ± 25 | 3T/H |

| Ø60mm | 6000mm | 1200℃ | 4.4T/H |

| Ø70mm | 6000mm | 1200℃ | 5.3T/H |

| Ø80mm | 6000mm | 1200℃ | 6T/H |

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(Steel bar) | PLC Control | IGBT200KW Quenching |

| Ø30-Ø70mm(Steel bar) | PLC Control | KGPS350KW Quenching |

| Ø80-Ø110(Steel bar) | PLC Control | KGPS450KW Quenching |

| Ø16-Ø32 mm(Sucker rod) | PLC Control | IGBT200KW Quenching |

As our induction heater is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.