Induction heating equipment for forging

Features:

Application: Forging , Forging , Rolling & Quenching

Material: Carbon steel, Brass,Iron,Alloy steel,Stainless steel,Aluminum

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product name:Induction Heating Equipment

We manufacture induction heating equipment that can bear very high temperatures efficiently. Used in a wide variety of applications like metal heating,metal hardening,metal tempering,metal annealing. The main customers belong to the iron and steel industry. The Inside of the induction heating equipment is constructed with best quality raw material.

Applications

● Forging & forming: Suitable for bar, pipe, plate, slab, billet, auto parts, fasteners

● Surface quenching: Suitable for Shaft, long bar, long pipe, sucker rod, drill pipe, drill rod

● Annealing: Suitable for Tube, pipe, pipeline, copper pipe

● Hardening & tempering: Suitable for Drill pipe, drill rod, piston rod, bolt, shaft

● Special application: Bar heating used for forging steel balls, rolling steel balls.

Benefits

● High -efficiency solid-state power units

● Standard units available in frequencies between 60 Hz and 10000 Hz

● Dual frequencies available for pre and post Curie heating

● Modular design for quick coil change to accommodate for different sizes

● Level control to centralize all bar sizes in coil opening

● Fully automated, PLC controlled material handing system

What Forever can do for you ?

● Providing the right and cost effective proposals for your project not matter it’s used forging, rolling, heat treatment or coating.

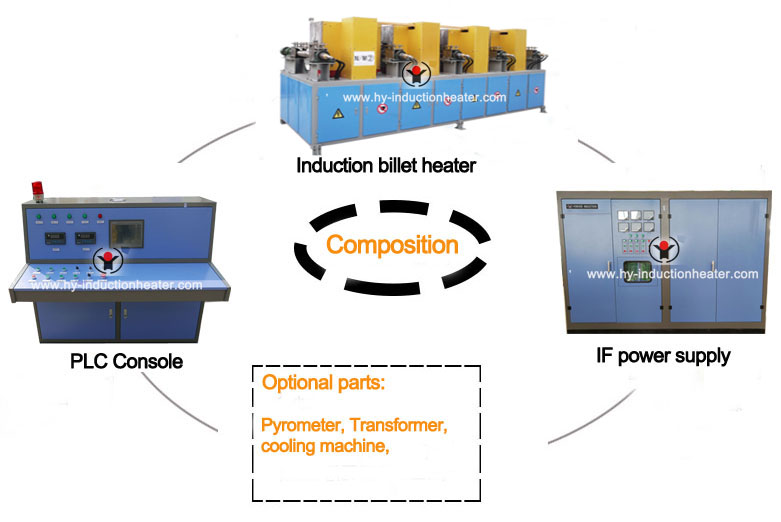

● Providing the whole set of induction heating system including induction heater, power supply, remote console, cooling tower, transformer or as per your requirement.

● Providing service for installing, debugging and training in your plant.

● Lifelong technical service and spare parts support or machine upgrading.

| Bar Diameter | Bar Length | Heating Temp. | Production capacity |

| Φ36-45mm | 1500mm | 1125°C ± 25 | 3T/H |

| Ø60mm | 6000mm | 1200℃ | 4.4T/H |

| Ø70mm | 6000mm | 1200℃ | 5.3T/H |

| Ø80mm | 6000mm | 1200℃ | 6T/H |

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3m-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

As our induction heater is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field