Induction Heating Equipment For Sale

Features:

Application: Forging , Forging , Rolling & Quenching

Material: Carbon steel, Brass,Iron,Alloy steel,Stainless steel,Aluminum

Application: Bar,flat plate,bar end heating, flat bar end, pipe ends,etc.

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Induction Heating Equipment For Sale

Forever factory, provides services and supplies for steel heat treatment plants either with new induction heating equipment and machinery projects or as modernization and upgrade of existing systems.Our Induction Heating Equipment has mature induction heating technology, and our parts are all from well know suppliers along with powerful after-sales service team support.

Applications

● Forging & forming: Suitable for bar, pipe, plate, slab, billet, auto parts, fasteners

● Surface quenching: Suitable for Shaft, long bar, long pipe, sucker rod, drill pipe, drill rod

● Annealing: Suitable for Tube, pipe, pipeline, copper pipe

● Hardening & tempering: Suitable for Drill pipe, drill rod, piston rod, bolt, shaft

● Special application: Bar heating used for forging steel balls, rolling steel balls.

Advantages

● High efficiency

● Proven & mature Design

● Reduced customer start up time

● Advanced PLC control, power & temperature control

● Quick release connections for both power & water

● All the cables and capacitors are well protected for long life performance

Forever induction heating equipment features

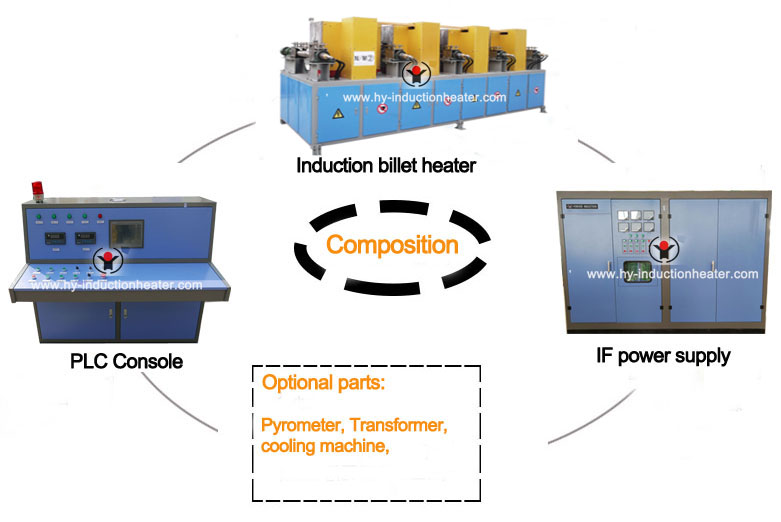

● Complete set of induction heating equipment including cooling, power supply and transformer.

● Uniform heating, the temperature difference from the billet surface to the core is very small and the temperature fluctuation is only 10℃.

● No harmonic pollution. This heating method is clean, energy efficient and efficient.

● Maintenance: users only need to repair induction heating coil every year.

● Responsible for installation, commissioning and training.

● Setting pyrometer for the induction heating system to display the heating temperature.

Successful cases

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-v110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3m-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

As our induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at sales@foreverfurnace.com for more detailed price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.