Induction furnace cooling system

Features:

The complete set of equipment for a closed cooling tower consists of a main unit, a water tank, a circulating water pump, and an electrical control cabinet. The host consists of a shell, a heat exchanger, a fan, and a spray water pump Composed of components such as water collectors, sinks, and pipeline valves.

Product Detail

Application Video

Product Tags

The complete set of equipment for a Closed cooling tower consists of a main unit, a water tank, a circulating water pump, and an electrical control cabinet. The host consists of a shell, a heat exchanger, a fan, and a spray water pump.

Composed of components such as water collectors, sinks, and pipeline valves. During the working process, the main circulation pump for the cooling medium (soft water, oil, or other liquids) is driven.

Circulating between the heat exchanger and the cooling equipment, the spray water is evenly sprayed onto the heat exchanger, forming a uniform water film on the outer surface of the heat exchanger,

Cold air enters the tower through the air inlet below the tower and flows counter current with the spray water through the surface of the heat exchanger. There are two ways of heat exchange in this process, namely cold air

The heat conduction between air and cooling medium, as well as the heat exchange caused by the evaporation of spray water, results in saturated hot and humid air being discharged into the atmosphere by a fan after absorbing heat.

The remaining spray water flows into the water tank at the bottom of the tower and is then transported to the spray system by a water pump. By repeating this process, the cooling medium inside the heat exchanger is obtained

Cooling down.

There are two operating modes for closed cooling towers. Air cooling, air cooling+spray. The switching between the two modes is automatically performed by the electronic control system according to the requirements of the working conditions

We are currently saving energy and reducing consumption.

(1) Application scope of Induction furnace cooling system :

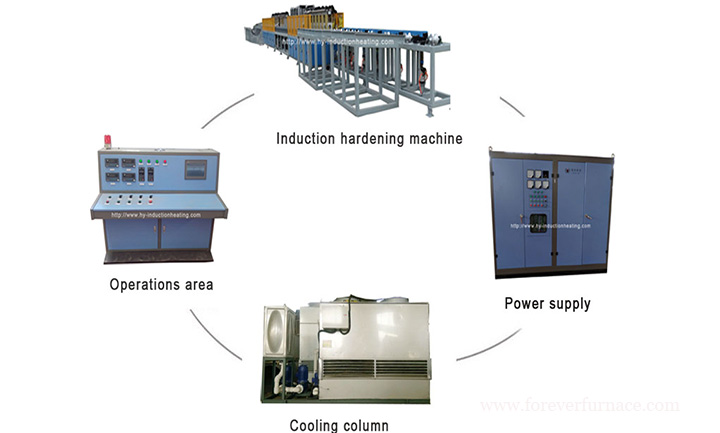

1. Induction heating and metal melting equipment, such as high and medium frequency quenching equipment, medium frequency power supply and electric furnace, induction heating furnace, insulation furnace, etc

But.

2. Cooling of circulating water for various reactors and condensers in the chemical industry.

3. Cooling of large motors, diesel engines, rectification equipment, welding equipment, hydraulic stations, and continuous casting equipment.

4. Cooling of large molds such as metal die-casting molds, injection molds, etc.

5. Cooling of industrial solutions, such as quenching solutions, electroplating solutions, etc.

(2) Advantages of closed cooling tower:

1. The fully enclosed circulation of the cooling medium can prevent impurities from entering the cooling pipeline system and the evaporation loss of the cooling medium.

2. Using soft water as a cooling medium, it does not scale, does not block pipelines, and has fewer malfunctions.

3. The dual cooling method of air cooling and spray water evaporation heat absorption has high cooling efficiency.

4. The device has a small volume, occupies a small space, is easy to move and place, and does not require the construction of a water tank.

5. Adopting automated intelligent control, the cooling mode can be automatically changed according to the requirements of the I condition, and the operation is simple and reliable.

6. Widely used, it can directly cool non corrosive media such as quenching fluids, oils, alcohols, etc. for heat exchangers, with no loss of media and stable composition.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.