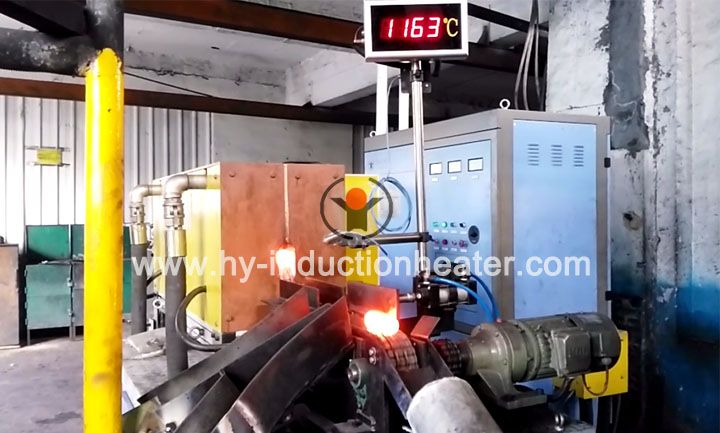

Bar billet Induction Forging Heating equipment

Features:

Control system: SIEMENS PLC controller

Temp.control:Closed-loop control

Transmission system:Table roller

Product Detail

Application Video

Product Tags

Bar induction forging heating equipment

Induction forging process refers to using the induction heater to heat metal bar, rod, billet or bloom before prior to forging. After heating up the material, the forging process will be done on different types of machines: Forging hammer, mechanical press, hydraulic machine, screw press etc.

The approximate hot forging temperatures of the most commonly used industrial materials are:

• Steel 1200º C

• Brass 750º C

• Aluminum 550º

Forging round bars with induction heating

Advantages

- High heating speed, less oxidation

- Lightweight and space-saving

- Energy saving, less pollution

- High degree of automation, full automatic operation can be realized

- Easy to control heating time and temperature, ensuring good quality of forging work piece.

Square billet induction forging furnace

Forever manufacture induction billet heater machine for forging applications which are designed for efficient heating of circular or square section billets. Our billet induction heater for forging includes pusher type billet feeder, billet heater and medium frequency power supply.

Advantages

- 100% successful start rate,no need pre-heating

- Precious temperature control and PLC control

- Increased production rates

- Reduced scaling

- Increased die life

Billet sorting induction forging furnace

Including medium frequency power supply, control unit, induction heater, discharge unit(three sorting system). With sorting system, the equipment can sort the billet at different temperature requirement aromatically when forging billet.

Induction forging aluminum bar

With induction heating method for forging, our induction forging equipment output power Repeat consistency is good as we use Distribution Cabinet with all-digital precision control, which can ensure that each work piece can be heated to the same temperature. The same temperature in the mass production can guarantee next process smooth and safe operation. Compared with the slow heating method such as flame, induction heating can reduce the surface oxidation of work piece obviously. Rapid heating process can improve production efficiency, but also reduce the energy significantly, saving production costs.

Forever aluminum bar induction forging furnace provides fast, safe and reliable heating for aluminum bar or billet forging. Please let us know your aluminum bar or billet size, production capacity and heating requirement, then we will provide you suitable induction forging furnace at affordable price.

Forever induction heating equipment series:

Steel ball production line Induction billet heater Hardening and tempering production line

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.