Bar Induction Heating Forging Equipment

Features:

Application: Forging & Forging

Material Heated:Carbon Steel, Aluminum, Brass

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Bar induction heating forging furnace in China

Typical Application:

Forever is the professional manufacturer of induction forging equipment in China, which is used for forging rod,billet of copper and steel. With over 20 years of experience, Forever has too much references for various kinds of induction forging equipment.

Induction forging process refers to using the induction heater to heat metal bar, rod, billet or bloom before prior to forging. After heating up the material, the forging process will be done on different types of machines: Forging hammer, mechanical press, hydraulic machine, screw press etc.

Material heating temperature for hot forging:

• Steel 1200º C

• Brass 750º C

• Aluminum 500º C

Induction forging equipment consists of:

IF control power supply, capacitor cabinets, furnace body (aluminum or steel), machinery (hydraulic) Pour heater installations, water distributor, crucible mold (graphite crucible, iron crucible), water-cooled cables, connectors Copper

NEW TYPE power supply

● Power saving 10% -15%:No harmonics, high power factor, load output voltage is high, the load coil current is low,small power consumption.

● Using special transformer for electric furnace.

● 100% successful starting.Reliable frequent starting is available.

● The furnace has high reliability: This product uses the latest DSP control technology, with reasonable structure, easy commissioning & reliable performance, which has automatic protection functions including water temperature, water pressure, phase shortage, over-current, under-voltage to ensure The product is running in stable and reliable condition.

● Adopt famous brand components which reduce fault rate and make sure the equipment can run reliably, thereby reducing the shutdown probability caused by failure.

● Advanced technology & Easy maintenance: Having simple structure,perfect protection for control circuit & the most advanced touch screen control, our power supply can show complete failure and find the error.It adopts DSP control technology, which has a high processing speed, which ensures the efficient and orderly operation of the device functions. real-time computing function and real-time simulation and simulation capability.

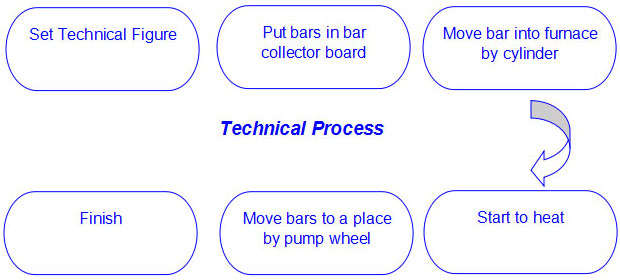

Forging technical process

| Bar Diameter | Bar Length | Heating Temp. | Power |

| Ø 16 mm | 300mm | 950℃ | 250KW/4000Hz |

| Ø 31-80 mm | 70-480mm | 1250℃ | 500KW/2500Hz |

| Ø 120 mm | 1500mm | 1250℃ | 2000KW/1000HZ |

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3m-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

As our billet induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at tom@foreverfurnace.com for Customized price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.