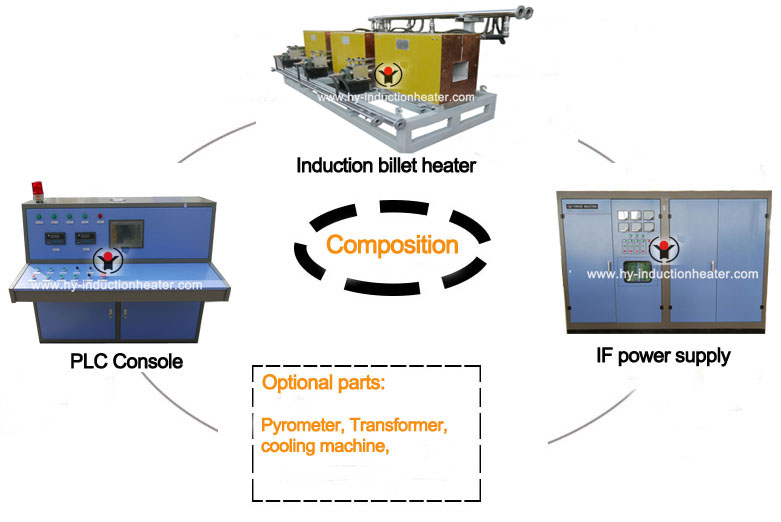

Induction billet heating equipment

Features:

● Uniform heating from surface to the core, from head to tail

● No harmonic effect on the grid

● More successful cases

Product Detail

Application Video

Product Tags

Product Name: induction billet heating equipment

Typical Application:

Induction heating is fast, precise, clean, energy efficient, controllable and repeatable. Forever induction billet heating equipment adopts mature induction heating technology, superior raw material and closed-loop temperature control system, which has been applied in Taiwan and Vietnam users’ plant.

● Available for round billet, square billet, pipe billet

● Main control system: Siemens PLC control system

● Temperature measurement: Infrared thermometer

● More successful cases

There is two kinds of methods for billet heating production line:

1.Cold billet heating–Our billet induction furnace will heat the billet from room temperature to 1200 ℃ for rolling;

2. Billet online heating–After the billet discharging from continuous casting machine, it need to regain heat before charging rolling mill.Then our billet induction furnace is playing an important role that reheating the billet to rolling temperature.

Features for induction billet heating equipment

● IGBT(SIEMENS) technology, high conversion efficiency

● Much more efficient than gas-fired and coal-fired method

● 100% start-up success rate; power factor > 95%

● Perfect and complete protection functions, increasing machine’s reliability & stability

● No special foundations required, Low operating cost, Easy operation

● Modular design, ease of maintaining and repairing

NEW TYPE POWER SUPPLY for induction billet heating equipment

● Power saving 10% -15%:No harmonics, high power factor, load output voltage is high, the load coil current is low,small power consumption.

● Using special transformer for electric furnace.

● 100% successful starting.Reliable frequent starting is available.

● The furnace has high reliability: This product uses the latest DSP control technology, with reasonable structure, easy commissioning & reliable performance, which has automatic protection functions including water temperature, water pressure, phase shortage, over-current, under-voltage to ensure The product is running in stable and reliable condition.

● Adopt famous brand components which reduce fault rate and make sure the equipment can run reliably, thereby reducing the shutdown probability caused by failure.

● Advanced technology & Easy maintenance: Having simple structure,perfect protection for control circuit & the most advanced touch screen control, our power supply can show complete failure and find the error.It adopts DSP control technology, which has a high processing speed, which ensures the efficient and orderly operation of the device functions. real-time computing function and real-time simulation and simulation capability.

More adaptable for load: New type IF induction power supply has self-adaptive function with angle adjustment. No need to adjust power supply while replacing inductor, and the equipment can automatically run in the best condition.

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3m-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

As our induction heater is all customized, please tell us your billet section size, length, heating temperature and production capacity, then we will give you solution and best price.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.