Induction annealing furnace

Features:

Application: Annealing

Suitable for : Tube,Pipe, Wire,Strip

Pipe Diameter Allow: Φ60-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name: Induction annealing furnace

Typical Application:

Induction annealing furnace is widely used for annealing heat treatment for bars, rods, pipes, tubes etc. The purpose of induction annealing furnace is to reduce hardness to improve plasticity and toughness, remove residual stress, or achieve the desired physical properties.

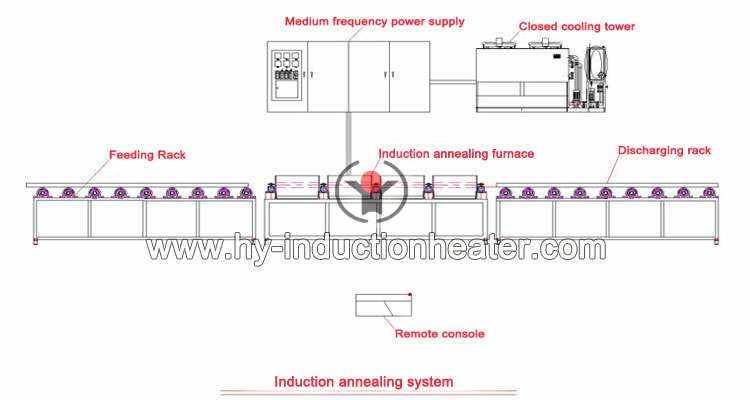

Induction annealing furnace composition

● Transportation system including storage platform, feeding device, discharging device and receiving platform

● Induction heating power supply

● Induction heating coils

● PLC console

Optional parts

● Transformer

● Infrared thermometer

● Cooling System

● Low power supply cabinet

Introduction for induction annealing furnace

The copper tube for induction annealing furnace adopts high quality T2 oxygen-free thick-walled tube.

After precision calculation and mechanical winding and shaping with import refractory cement, it will be in a whole with features of high strength and durable.

Induction heater both ends adopt whole copper for covering, the furnace frame adopts high strength aluminum alloy, which not only improve the strength of the furnace, but also reduce the leakage of magnetic, thus reducing the heat of the furnace parts, reducing the energy loss.

Induction furnace water supply is using stainless steel water supply and equip with stainless steel quick change joints, which make replacing induction heater more convenient. Both sides of the induction heater are used 8mm thick polyurethane insulation board with features of insulation performance, high strength.

Conveying mechanism of induction annealing furnace

The conveying mechanism of the furnace adopts pinch roller device. The roller is made of non-magnetic stainless steel. The upper and lower shafts are water cooled by rotating water cooling joint, which reduces the deformation and maintains the strength of the shaft. Furnace cabinet has enough strength and rigidity for easier equipment installing. The bottom of the rack set adjustable anchor for convenient equipment installing. So the equipment appearance will be nicer.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.