IF hardening

Features:

Application: Hardening & Quenching

Material Heated:45#,40Cr,42CrMo,65Mn

Bar Diameter Allow: Φ20-110mm

Pipe Diameter Allow: Φ60-300mm

Length Allow:Not limited

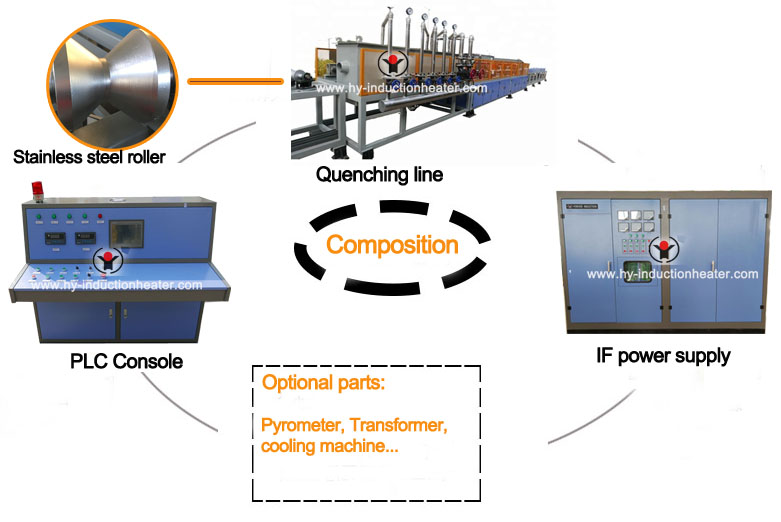

Product Detail

Application Video

Product Tags

Product Name: IF hardening furnace

Typical Application:

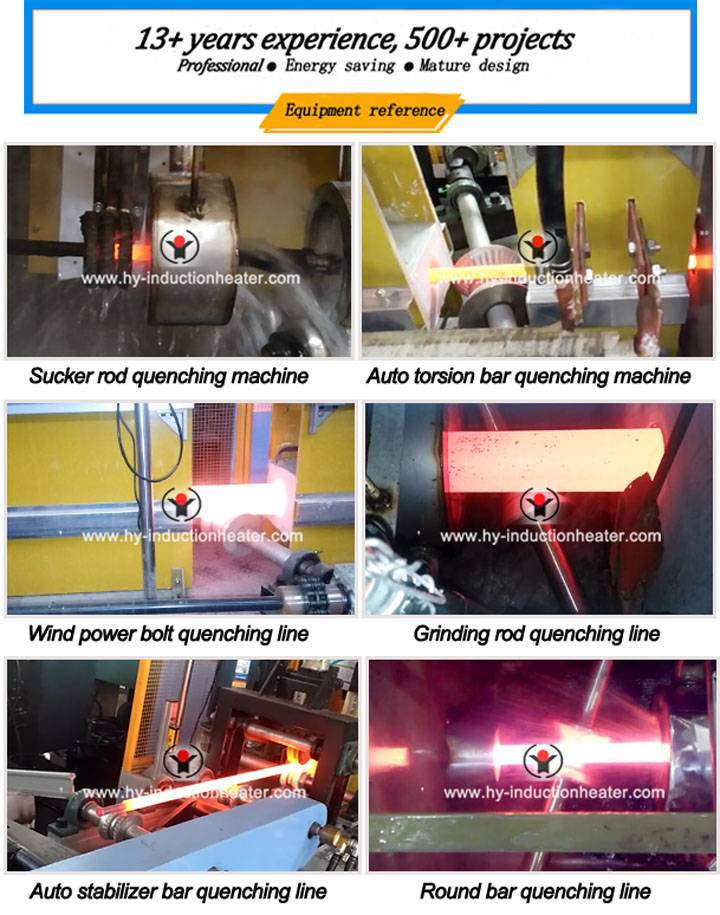

Applicable to IF hardening of 45#,40Cr, 42CrMo, 65Mn. Current applications include IF hardening for round bar, piston rod, grinding rod, sucker rod, anchor bolt,blade, steel wire.

IF hardening technique (limited to certain high strength alloy steels) that reduces the residual internal stresses and distortion resulting from non-uniform transformation and thermal shock typical of conventional oil quenching.

Advantages of IF hardening furnace

● High reliability:Adopt famous brand components of IGBT power supply which reduce fault rate and make sure the equipment can run reliably.

● Safe and reliable. There are reliable protection covers for the mechanical rotating parts,which is durable and very safe for operators. Automatic protections for water temperature, water pressure,phase shortage, overcurrent and undervoltage.

● Easy installation & commission and simple operation.

● Transmission mechanism frame has sufficient strength and rigidity for ease of installation of equipment

● Feeding and discharging table is using high quality steel welded firmly, which can withstand a certain impact load.

High automation of IF hardening furnace

● If hardening furnace feeding system: roller table + power press roller, each shaft driven by independent motor reducer, independent frequency converter control; flexible design of speed difference output, sectional control of operating speed.

● Roller electrical isolation: Aiming at the problem of spark between workpiece and roller, we designed a strong and durable electrical isolation system for roller, which completely solved the problem of lightening damage of workpiece.

● The industrial computer system: Real-time display of the working parameters, workpiece parameters memory, storage. printing, fault display, alarm and so on.

● Formula Management Function: Powerful Formula Management System. After selecting the parameters of steel grade to be produced, relevant parameters can be automatically invoked without manual recording, consulting and inputting the parameters required for various workpieces.

● Full computer control is implemented. All the process parameters are stored in PLC. The operator can start the steel bar quenching furnace by adjusting the corresponding process parameters.

Successful cases

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(Steel bar) | PLC Control | IGBT200KW Quenching |

| Ø30-Ø70mm(Steel bar) | PLC Control | KGPS350KW Quenching |

| Ø80-Ø110(Steel bar) | PLC Control | KGPS450KW Quenching |

| Ø16-Ø32 mm(Sucker rod) | PLC Control | IGBT200KW Quenching |

| Shaft diameter | Shaft length | Heating Temp. | Quenching depth | Production capacity |

| Ø16 | 4m | 900℃ | 1.1~2.3mm | 120 PCS/H |

| Ø25 | 4m | 900℃ | 1.1~2.3mm | 60 PCS/H |

As our bar pipe heat treatment furnace is all customized, the above parameters are only for your reference.

Welcome to contact us at tom@foreverfurnace.com for more detailed price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.