Hardening and tempering furnace

Features:

| Application | Hardening and tempering process |

| Brand | Yuantuo |

| Material | Carbon steel, alloy steel |

| Power | 100-8000KW |

| Workpiece | Bar, pipe, plate, billet |

Product Detail

Application Video

Product Tags

Yuantuo is committed to the production and design of hardening and tempering heater with more than 13 years of rich experience. The process is mature and stable, and the operation is reliable. The hardening and tempering heater has one-button operation, and one person can control the entire set of hardening and tempering heater system. The production line has complete data monitoring, process records, and strong traceability in the production and operation of the production line. The customized man-machine interface of the hardening and tempering heater always displays production data. The professional technical team provides you with high-quality induction heating equipment and Satisfactory service.

Basic information for hardening and tempering heater

| Application | Hardening and tempering process |

| Brand | Yuantuo |

| Material | Carbon steel, alloy steel |

| Power | 100-8000KW |

| Workpiece | Bar, pipe, plate, billet |

Hardening and tempering heater system configuration:

● Hardening frequency power range: KGPS160-1300KW

● Tempered medium frequency power supply range: KGPS160-750KW

● Induction heaters for hardening and tempering (including capacitor, water lines, gas lines, etc.)

● Closed cooling system for medium frequency power supply and inductor

● Copper connection wire (connection between power cabinet and induction furnace)

● Input and output system (The roller is 304 non-magnetic stainless steel. The workpiece rotates and feeds at the same speed. The operation is stable, the speed is adjustable, the heating is more uniform, corrosion resistance, and long service life)

● Hardening and tempering sprinkler system

● The central console (including frequency conversion speed and temperature control, remote start, etc.) is used to operate the entire induction heat treating furnace.

● Infrared temperature measuring device for hardening and tempering(with Raytek infrared thermometer real-time display the temperature of the workpiece, so that the workpiece temperature uniformity can be seen at any time in the quenching and tempering process)

●PLC control system (can control the operation of the entire mechanical part, human-machine interface, all-digital, highly humane operation)

Yuantuo has professional engineers in the production of hardening and tempering heater. The design, process, manufacturing management and other details have many years of practical experience. The medium frequency power supply of hardening and tempering heater has SCR intelligent series resonance design. The rectifier is fully open;the power factor is high; the harmonic content is small; the heating speed is fast. After hardening and tempering, the workpiece can meet user’s requirement in toughness, tensile strength and straightness.

The heating method is continuous on-line heating, and the movement of the whole set of hardening and tempering production lines is automatically completed by the system under the control of the PLC. The complete production line adopts Taiwan Huayan IPC as the core control part, which can save, display and automatic record the system running parameters, temperature parameters etc.

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(bar) | PLC Control | IGBT200KW Hardening |

| Ø30-Ø70mm( bar) | PLC Control | KGPS350KW Hardening |

| Ø80-Ø110( bar) | PLC Control | KGPS450KW Hardening |

| Ø16-Ø32 mm(rod) | PLC Control | IGBT200KW Hardening |

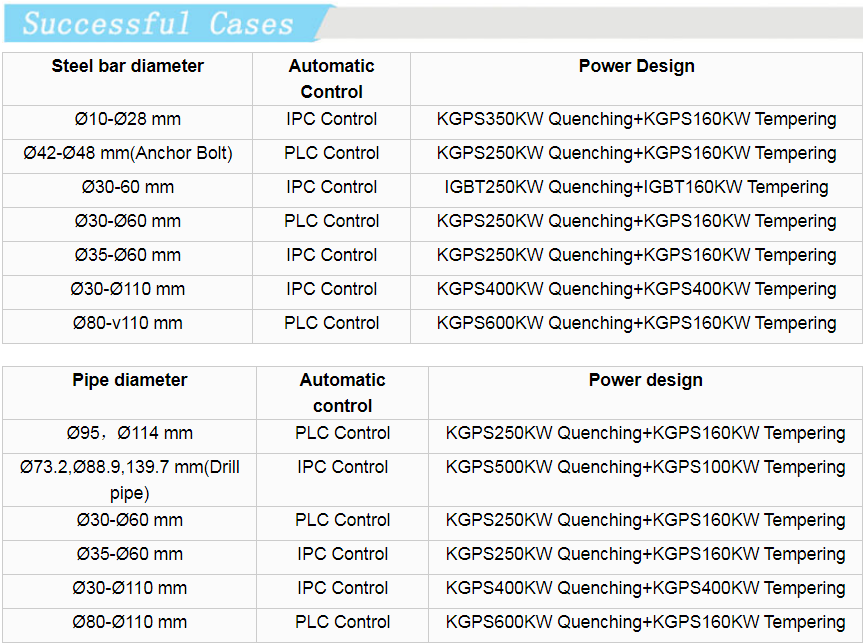

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.