Grinding rod induction quenching machine

Features:

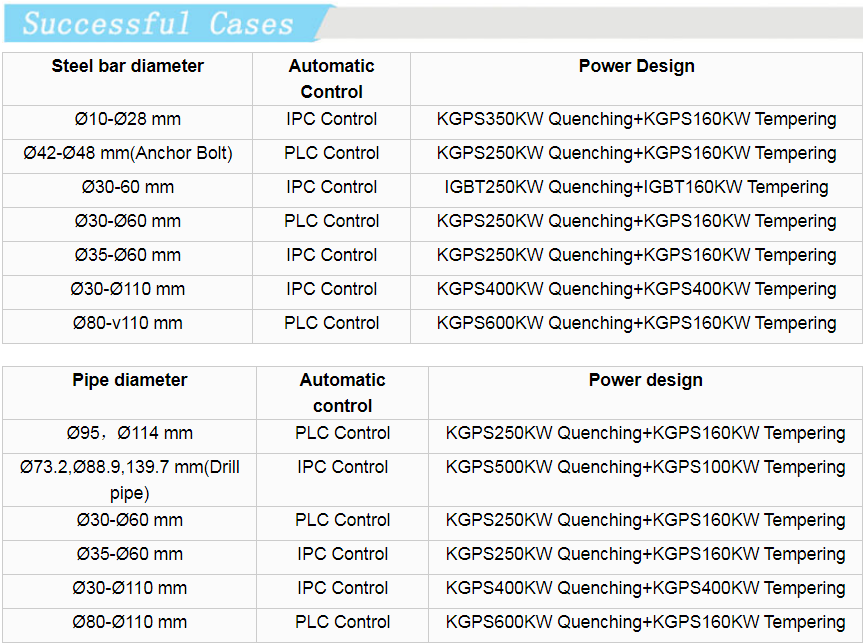

● Grinding diameter:ø40-150mm

● Tubing length: 2-8m

● Heating temperature:900-1000℃

● Material: Carbon steel

Product Detail

Application Video

Product Tags

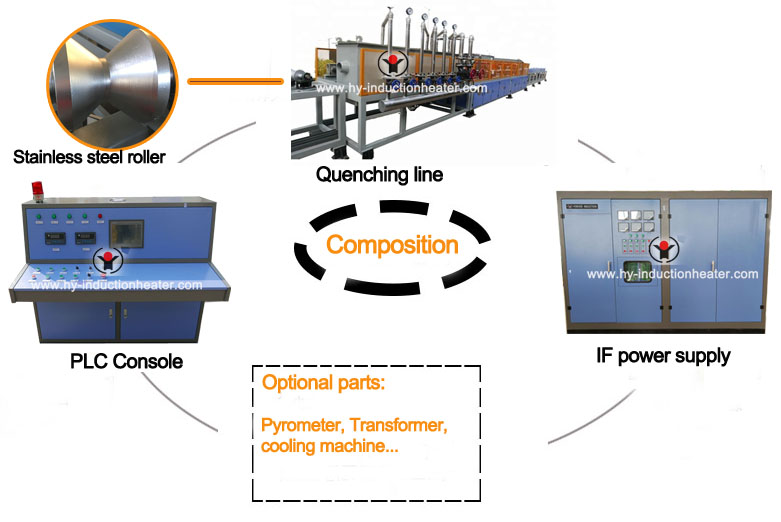

Grinding rod induction heat treatment machine

Forever has nearly 20 years of experience in the field of induction heat treating process and our grinding rod quenching machine has been proven successful operation in user’s plant. So far Forever has manufactured more than 10 sets of grinding quenching machines.

● Grinding diameter:ø40-150mm

● Tubing length: 2-8m

● Heating temperature:900-1000℃

● Material: Carbon steel

● Power required: 80-5000KW

Grinding rod quenching machine advantages

● The induction heater is using quick-change type, easy for maintenance and replacement.

● Conveyor roller adopts hollow water-cooled rotating roller, so the shaft will not be overheated during induction heating process.

● The grinding rod will rotate by itself during going forward to make sure the heating uniformity and quenching uniformity.

● The whole process of working has achieved fully automatic feeding, heating, quenching and receiving.

Grinding rod quenching machine control system:

● The system can record, save and check the tubing heat treatment process parameters.

● Good man-machine dialogue window, real-time monitoring of the entire system equipment running status.

● Process heating parameters can be automatically formed database and perennial save, ready for random checks

● Mechanical transmission system is stable, accurate, reduce man-made operation errors, reduce the failure rate.

● Through the thermometer, the system can detect and control for the heating temperature in every stage.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.