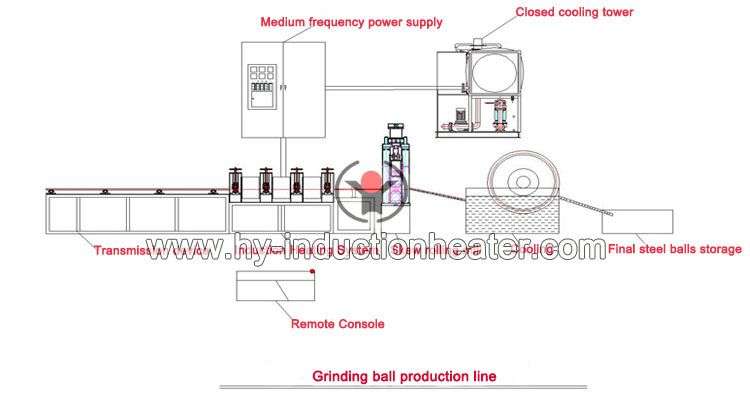

Grinding ball production line

Features:

| Application | Making grinding ball,steel balls |

| Power | 100 KW-8000 KW |

| Cooling Way | Cooling Tower |

Product Detail

Application Video

Product Tags

Product Name: Grinding ball production line

Typical Application:

Forever grinding ball production line is widely used in metallurgy,cement,thermal power,chemical industry,mining, ball grinding mill industry. Our grinding ball production line adopts induction heating furnace to heat bars or billet uniformly and rapidly and uses rolling mill to rolled bars into steel balls.The following 50-80 mm grinding ball production line is one of our successful cases.

Grinding ball production line workshop layout

Field working picture

Grinding ball production line configuration

● Material Storage and automatic Feeder: Programmable Logic Control automatic feeder system with 6m length

● Induction heating furnace: The power is designed as per your production capacity

● Rolling mill System: Rolling mill, Roller universal joint, Distribution Box, Reducer, motor (220KW AC frequency), motor mount, rollers

● Die for the grinding steel ball: As per your steel ball diameters

● Conveyor and quenching system: Conveyor hoist, Spiral quenching tank, Frequency speed Control

● Tempering furnace: Optional

● General operating console(It’s optional)

● Infrared Thermometer(It’s optional)

● Closed cooling tower

After sales service for Grinding ball production line

● Provide complete grinding ball production line

● Field installing & debugging;One year quality warranty period; long life technical service and spare parts support !

● Packing is suitable for ship by sea.

● Sales and after-sales person with fluent English will be at your service.

Manufacturer & supplier of various hot rolled steel ball production line, bars induction heating equipment, billet induction reheating furnace.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.