steel bar heating forging furnace

Features:

Application: Forging & Forging

Material Heated:Carbon Steel & Alloy Steel

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name:steel bar induction annealing furnace

Typical Application:

steel bar heating forging furnace is used for steel bar, steel rod, steel billet induction heating before forging, extrusion or bending.

Induction forging process refers to using the induction heater to heat metal bar, rod, billet or bloom before prior to forging. After heating up the material, the forging process will be done on different types of machines: Forging hammer, mechanical press, hydraulic machine, screw press etc.

Characteristics

- Medium frequency forge used induction heating furnace can heat billet diameter from 20mm-300mm.

- Maximum production rate 3T/Hour

- Medium frequency forge used induction heating furnace can heat Carbon steel, Stainless steel, Alloy steel, Aluminum Brass and Others

- Uniform heating temperature is good for mold of press machine.

- Heating rapidly reduces oxide skin on billet

- Quick water connections

- IGBT inversion technology & LC series circuit design achieve energy saving up to 15%-30% compared with SCR technology medium frequency forge used induction heating furnace

- Diode rectification technologies ensure high power factor –more than 0.95

- Color and language printed according to customer’s request

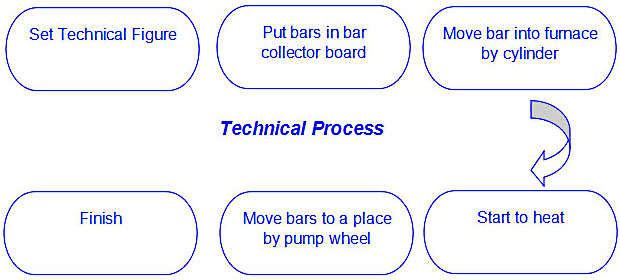

Technical process of Induction Heating forging furnace:

As our billet induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at tom@foreverfurnace.com for Customized price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.