Automatic Induction Forging furnace

Features:

| Application | Heating, reheating, preheating, forging, rolling, extrusion, hardening, annealing |

| Power | 100 KW-10000 KW |

| Non standard |

Professional Customization |

Product Detail

Application Video

Product Tags

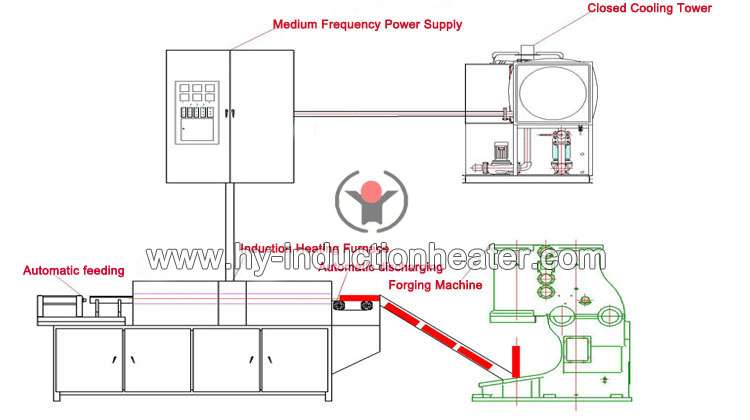

Product Name: automatic bar induction forging furnace

Application: Heating before bar forging, extrusion or shear

Material grade: Carbon steel, aluminum, copper alloy, Silver

Heating way: Electric induction heating

Loading way: Cylinder driven

Automatic induction forging heating furnace is produced by Forever in China, which is mainly used for through heating of steel bar and round billet befor forging. The user only need to tell us the workpiece size, product specification, heating temperature, technical requirement and presnet heating method, then our engineer will help you to choose the most suitable solutions as per your workshop conditions.

According to the user’s requirements, the automatic forging heating furnace can be configured in different ways: automatic feeding machine, discharging machine, discharge separator, closed cooling water circulation system and so on.

Main features for forging heating furnace

● High reliability; simple maintenance; perfect automatic protection functions of over voltage, over current, over heating, water shortage and so on.

● Digital automatic control for integrated circuit with manual,manual, automatic, semi-automatic control function.

● Automatic frequency tracking; power stepless adjustment; operator can master is within 10 minutes.

● Low power consumption.Saving electricity 40-60% than electrical tube and 20% than SCR.

● Infrared thermometer at the furnace discharging port and Siemens PLC closed loop control.

After-sales service commitment for forging heating furnace

● Free maintenance for non-human damage with one year and lifetime maintenance.

● long-term technical support;equip with inductor as per user’s requirement.

● Provide all the spare parts service.

● According to customer’s requirement, Forever can supply closed water cooling tower.

● Forever will be responsible for the installment and debugging of complete induction heat treating equipment and provide free technical training about operation and daily maintenance.

Our company focus on the production quality improvement and energy saving development over 20 years, specialized in manufacturing Induction heat treating equipment|IF electric furnace|induction quenching furnace|induction tempering furnace|forging heating furnace.

For more information, please refer to our website【http://www.hy-inductionheater.com/】

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.