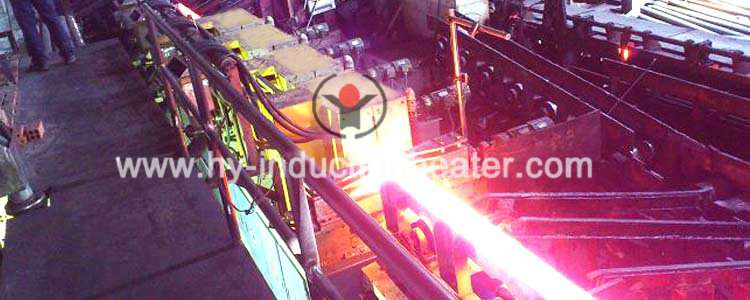

Electric induction heating furnace

Features:

| Application | Bar, pipe, tube, slab, billet, wire heating |

| Power | 100KW-8000KW |

| Non standard | Professional customization |

| Temp.control | Infrared thermometer |

Product Detail

Application Video

Product Tags

Engaged in developing and producing electric induction heating furnace for 12 years, Forever mature induction heating process has applied to bar heating,pipe heating, billet heating, wire rod heating, hardware heating and so on.

Product Name: Electric induction heating furnace

Typical application:Heating before forging, rolling, extrusion, shear or heat treatment.

Loading way: Cylinder drive

Temperature measuring device: Infrared thermometer at the outlet of the heater

Conveying model: Motor or chain

The induction coil is the core component of the electric induction heating furnace. After all, the induction coil is the part that actually transfers heat to the workpiece, which is winded with T2 copper tube and keep the induction coil in a good condition as much as possible and improve productivity. The core components of Forever electric induction heating furnace are all purchased from international famous brands, such as breaker, switch, button, touch screen, inverter and so on.

Performance of electric induction heating furnace

● Forever parallel and series resonant intelligent control technology, all-digital touch-screen operation, ranking the leading domestic and international forefront position

● Feeding system:Roller table+power double pitch, independent motor reducer drive for each axis , independent inverter control; flexible design speed differential output, section speed control.

● Recipe management function: powerful recipe management system–after selecting steel grade,slab parameters, this system can automatically call the relevant parameters, no need to manually record, check, input required parameters for various work piece.

● Temperature closed-loop system: The induction heating system adopts closed-loop control system which consists of America Raytek infrared thermometer and German Siemens PLC with high precision temperature control.

●The senior engineer team can provide excellent system solutions and Forever product manufacturing process strictly implement GB / T10067.3-2005 and GB / T5959.3-1998 national standards.

We are always aimed at providing the best quality induction heat treating equipment and excellent after-sales service. Even if you have any questions during process of electric induction heating furnace, you can also send us email.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.