Copper hot rolling heating furnace

Features:

Application: Forging & Rolling

Material Heated:Copper & Alloy Copper

Diameter Allow: Φ20-150mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

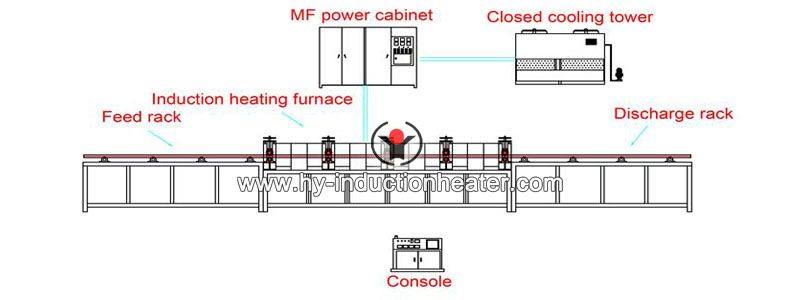

Having energy saving power supply & self-developed control system, our copper hot rolling furnace is used for copper or alloy copper induction heating before charging into rolling mills.

Product Name: Copper hot rolling heating furnace

Technical requirement

- Brass bar diameter : 80mm

- Brass bar length: 7000mm

- Heating temperature: 850℃

- Production capacity: 5-6 t/h

- Temperature control: Closed-loop temperature control system, which can adjust the heating temperature automatically.

Copper hot rolling heating furnace features

- Efficient and quick heating

- Accurate, repeatable heating

- Safe heating as there is no flame

- Equipped with infrared pyrometer and automatic feeder

- New type power supply, saving power

Induction for our NEW TYPE power supply

● Power saving 10% -15%:No harmonics, high power factor, load output voltage is high, the load coil current is low,small power consumption.

● Using special transformer for electric furnace.

● 100% successful starting.Reliable frequent starting is available.

● The induction heating furnace has high reliability: This product uses the latest DSP control technology, with reasonable structure, easy commissioning & reliable performance, which has automatic protection functions including water temperature, water pressure, phase shortage, over-current, under-voltage to ensure The product is running in stable and reliable condition.

● Adopt famous brand components which reduce fault rate and make sure the equipment can run reliably, thereby reducing the shutdown probability caused by failure.

● Advanced technology & Easy maintenance: Having simple structure,perfect protection for control circuit & the most advanced touch screen control, our power supply can show complete failure and find the error.It adopts DSP control technology, which has a high processing speed, which ensures the efficient and orderly operation of the device functions. real-time computing function and real-time simulation and simulation capability.

More adaptable: New type IF induction power supply has self-adaptive function with angle adjustment. No need to adjust power supply while replacing inductor, and the equipment can automatically run in the best condition.

Welcome to contact us at tom@foreverfurnace.com for customized detailed price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.