Billet induction heating machine

Features:

Application: Forging , Forging & Rolling

Material Heated:Carbon Steel & Alloy Steel

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name: Billet induction heating machine

Typical Application:

Our Billet induction heating furnace is used for forging and rolling rod,billet of copper and iron.

Forever focus is to lead the market in top quality heating and billet induction heater by providing automatic and innovative systems for long-life features.

Billet induction heating machine application

- Hot rolling/ reheating of Bars

- Hot rolling/ reheating of Billets

- Hot rolling/ reheating of Slabs

- Hot rolling/ reheating of Plates

- Hot rolling/ reheating of Blooms

Advantages for Billet induction heating machine

- High efficiency

- Proven & mature Design

- Reduced customer start up time

- Advanced PLC control, power & temperature control

- Quick release connections for both power & water

- All the cables and capacitors are well protected for long life performance

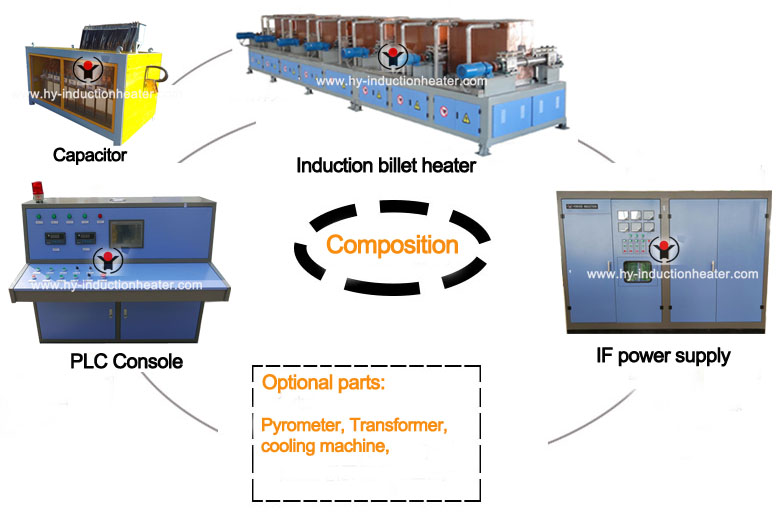

The Billet induction heating machine consists of a furnace cabinet, inductor, feeding roller, guide roller, reducer and so on. The roller are made of non-magnetic stainless steel, and we input water for cooling to avoid the thermal deformation and maintain the wheel shaft strength.The furnace cabinet has enough strength and rigidity to support inductors.

In order to make installment easier, we set adjustable anchor on the bottom of frame. Induction heater copper tube adopts high quality T2 oxygen-free thick-walled tube.After precision calculation and mechanical winding and shaping with import refractory cement, it will be in a whole with features of high strength and durable. Induction heater both ends adopt whole copper for covering, the furnace frame adopts high strength aluminum alloy, which not only improve the strength of the furnace, but also reduce the leakage of magnetic, thus reducing the heat of the furnace parts, reducing the energy loss. Induction furnace water supply is using stainless steel water supply and equip with stainless steel quick change joints, which make replacing induction heater more convenient.

Both sides of the Billet induction heating machine are used 10mm thick polyurethane insulation board with features of insulation performance, high strength.The PLC parameters can be set to automatically control the production efficiency and heating temperature, and can be completely matched with the rolling speed of the rolling mill to achieve rolling at the same temperature; secondly, compared with gas furnace and regenerator, there is almost no oxidation skin on the billet surface with induction furnace. The heating is uniform and can instant start and stop. The occupying area is small and can achieve automatic production line to avoid heating billet waste caused by subsequent mechanical failure.

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3m-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

As our billet induction heater is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.