billet induction reheating furnace

Features:

Application: induction reheating

Workpiece: steel billet

Length Allow:50-500mm

Product Detail

Application Video

Product Tags

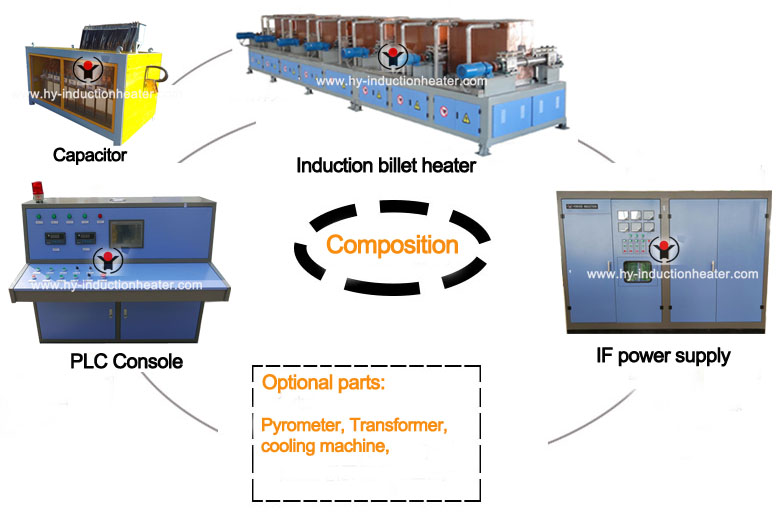

Forever Electrical and Mechanical Specialty provides on-line heating furnace for billet. The whole process is controlled by PLC intelligent automatic program.billet induction heating machine is safe and energy-saving, with high automation, stable product quality, high production efficiency and simple operation.

Process parameters and characteristics of on-line heating furnace for billet:

Name of equipment: billet on-line heating furnace, billet on-line heating equipment, steel billet induction heating equipment

Steel material: plain carbon steel alloy steel, etc.

Billet size range: (6mm * 6mm) – (500mm * 500mm)

Billet Length Range: Over 0.5 M

Advantages of billet induction reheating machine:

1. The induction reheating furnace has different degrees of bending according to different kinds of workpieces. If the bending degree of the billet is greater than 3m m/m before entering the furnace, the size of the inductor can be adjusted according to the bending degree of your steel.

2. The surface temperature of billet heated by on-line heating electric furnace before entering the furnace and the temperature of billet discharging from the furnace. The billet is heated uniformly, without overburning and cracks. The tensile strength and straightness can meet the needs of users.

3. The whole heating process of billet heating equipment can be automatically controlled by PLC, and production records such as heating quantity can be displayed timely.

4. Feeding and guiding system: each axis is driven by an independent motor reducer, with multi-axis drive and single frequency converter control, so that the multi-axis operation can be synchronized. The components are selected by well-known brands, with reliable quality and stable operation.

5. The billet reheating furnace adopts 12-pulse or 24-pulse KGPS100-1000KW single power supply with series resonance intermediate frequency double rectifier or parallel power supply.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.