Bar surface hardening machine

Features:

| Material | S45C, SCM440, 42CRMO4, 16MNCR5, 40CR4 |

| Length | ≥2000mm |

| Power | 100-8000KW |

| Control system | Closed-loop temperature control |

Product Detail

Application Video

Product Tags

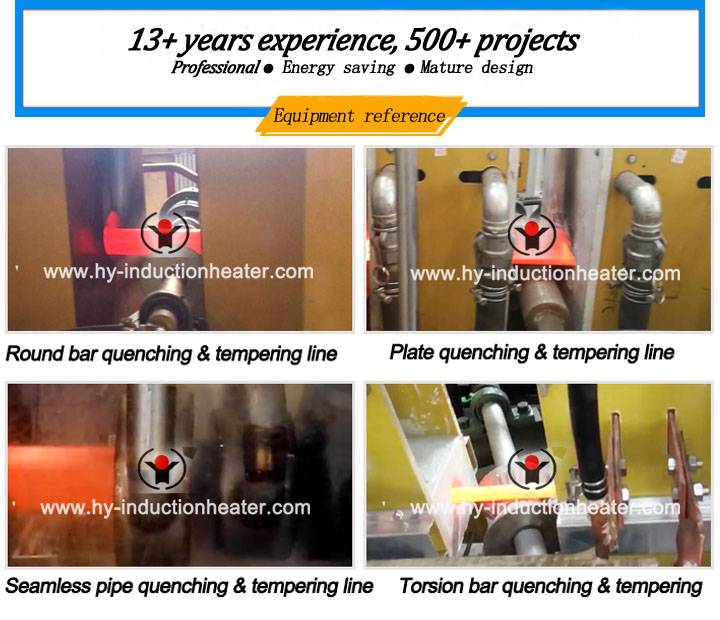

Forever bar surface hardening machine adopts superior parts to assembly. With more than 18 years of experience, our bar surface hardening machine can be customized produced according to customer’s request. Welcome to visit our factory. Almost every month we will have bar surface hardening order, so you can see the machine anytime when you come.

Basic information for hardening and tempering heater

| Material | S45C, SCM440, 42CRMO4, 16MNCR5, 40CR4 |

| Brand | FOREVER |

| Working mode | Automatic |

| Power | 100-8000KW |

| Control system | Closed-loop temperature control |

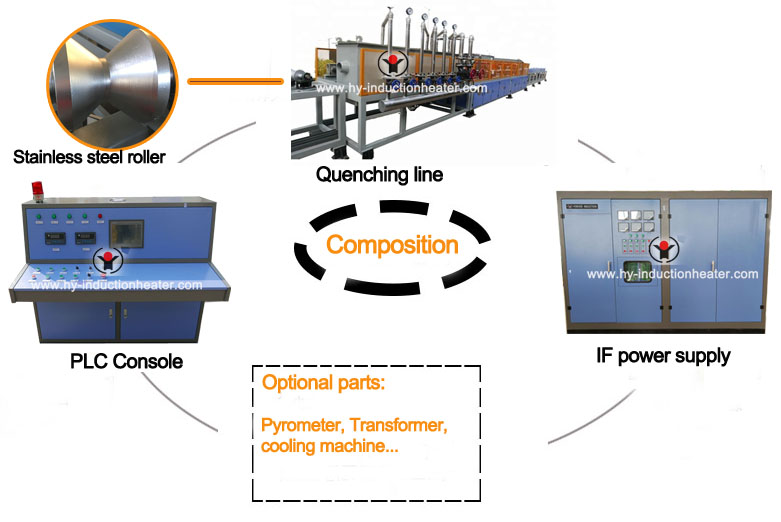

Complete sets of bar surface hardening machine consists of: feeder(including inverter motor, roller and automatic turning device ), induction heat treatment furnace, hardening device, receiving platform, induction heating power supply, PLC control system. As per specific request, we can also provide cooling system, infrared thermometer and power transformer.

The advantages of bar surface hardening machine:

• The continuous heating equipment for round steel adopts CNC technology, which has the functions of continuous, simultaneous and segmented;

• Configurable integrated quench liquid circulating cooling system;

• Using profile structural fuselage, durable.

• Use CNC system or PLC and variable frequency speed control system to achieve workpiece positioning, scanning, and achieve fully automated production through connection with PLC.

Bar surface hardening machine after-sales service:

1. After signing the contract, we will provide the layout drawing of equipment and site building drawing.

2.After the bar surface hardening machine finish production, we will send professional technician to install and adjust.

3.The technician will teach the local operators how to use the machines

4.12 months warranty period since the machine get approval by users.

5.Long term technical service and spare parts support .

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(bar) | PLC Control | IGBT200KW Hardening |

| Ø30-Ø70mm( bar) | PLC Control | KGPS350KW Hardening |

| Ø80-Ø110( bar) | PLC Control | KGPS450KW Hardening |

| Ø16-Ø32 mm(rod) | PLC Control | IGBT200KW Hardening |

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.