Which manufacturer can produce long bar induction heat treatment machine ? Here is a comprehensive production plan for you.

Over the past 20 years, Forever has always adhered to the production principle of “faithful manufacturing, the pursuit of better quality” and respected the choice of customers of induction heating furnace. Making every details perfect, which is also the fundamental to make our factory brand bigger and stronger. Customer demand oriented, to meet customer requirements for product quality is the brand spirit of our company. For example, the long bar induction heat treatment machine has always adhered to the industry’s higher standards of spare parts and electronic components accessories and keep a long term business relationship with a number of well-known domestic and foreign electrical components to ensure that the quality of the long bar induction heat treatment machine is consistent.

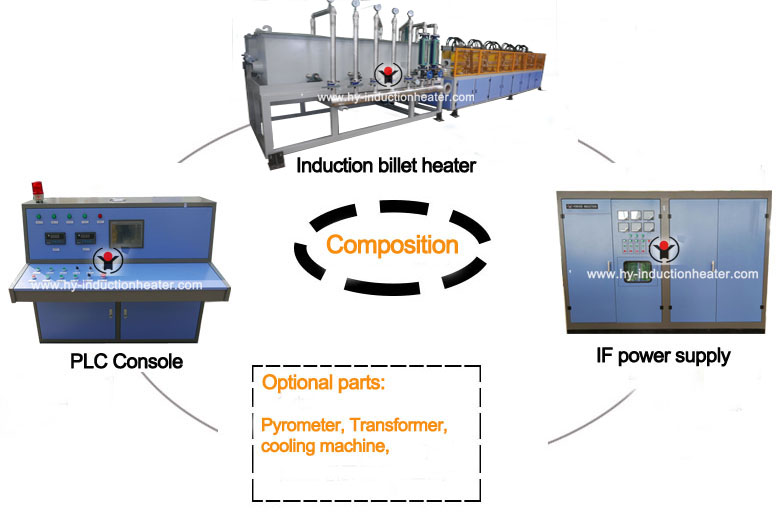

During the research and development of the long bar induction heat treatment machine, the professional technicians from Germany and the technical engineers with 30 years’production experience in China have been invited to come to the plant for technical exchange, and they have been invited to work out suggestions for the development of the continuous quenching and tempering furnace. In the production of the heat treatment machine for long bars, materials science, heat treatment, fluid science,intelligent control and electricity are covered.

A lot of experience has been accumulated in the past projects, and a unique formula has been formed: current frequency, heating rate, workpiece feed and rotation speed, spray cooling and workpiece angle, flow and pressure, cooling water temperature and many other parameters that affect the final performance of the workpiece. For users with different thickness and specifications, users only need to choose the serial number for them. The long bar induction heat treatment machine can be started by one button, and all parameters are processed according to the technological formula to ensure that the parameters of sheet properties are consistent.

The intelligent induction heating power supply adopts advanced parallel resonance design and the dynamic model of the inverter based on phase-shifted power-modulated parallel resonance is established by using data sampling method. It makes the quenching and tempering operation of long bar heat treatment machine mature and stable and has more advantages in the high power range of 3000KW or more. IGBT induction power supply and inductor always keep the best match, full power output, turn-off loss is small, reactive power component is small, compared with the traditional inverter, it is saving power 15-30%.

The quenching cooling sprinkler is made of 304 stainless steel. The long bars are heated by induction heating furnace at high speed and passed through the quenching sprinkler. The high pressure cooling water sprays out from the sprinkler hole on the inner wall of the sprinkler to quench the bars.

Since the establishment of the factory, Forever has always put the customer’s needs and concern in the first place, with a better product interpretation of the “user needs” as the core elements.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction hardening and tempering furnace is glad to be your partner in the field of induction heating.

Post time: 10-30-2018