What is energy saving and efficient heat treatment equipment? Forever long bar induction heat treatment machine can make you satisfied !

In the heat treatment industry, energy saving, environmental protection, high efficiency and so on are all the goals that every heat treatment enterprise wants to achieve, but really there is such a device to meet users? Of course, Forever long bar induction heat treatment machine can meet all your requirements for your heat treatment.

Over the years, Forever has already formed a strict quality management production system, every set of long bar induction heat treatment machine is strictly in accordance with the national quality management system standards, each procedure is responsible to people, each procedure is to achieve the ultimate to ensure the stability of heat treatment equipment quality.

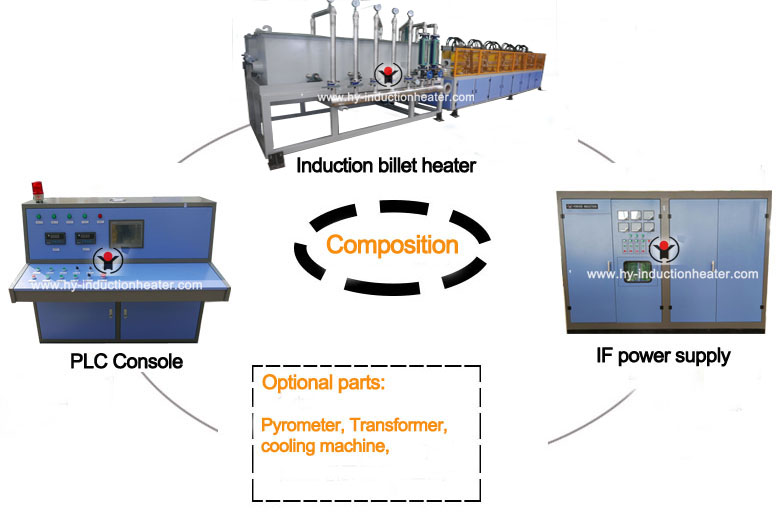

Forever long bar heat treatment machine has high heating speed, less soxidation decarbonization: due to the principle of medium frequency induction heating for electromagnetic induction, its heat generated in the work itself. Because of the fast heating speed, so the oxidation is very little, heating efficiency is high, process repeatability is good. From loading material to feeding and heating, the system can be fully automatic operation. At the same time, the control system has the modes of “automatic” and “manual”. At the beginning, when we need to debug the machine, we can use manual mode to obtain every technical datas for one lot of steel bars. After getting the parameters, we can mark it the recipe 1 to input the PLC system, then the operator only need to recall this recipe 1 when they need the same parameters. If you require many processes parameters for different grade and size of long steel bars, you can debug firstly and then input all the parameters as recipe 2, recipe 3 and so on, after that, you just need to choose the corresponding recipe to start working.

The induction heating coil will be designed as per different long bar sizes, During the working process, user can replace the induction heating coil to achieve heat treatment for different size of bars. For this step, you only need to disconnect the copper bar and the water pipe and replace the another set, then the system power supply power and frequency will automatically adjusted as per different load, which bring great convenience to the users during operation. The long bar induction heat treatment machine can start to work soon for different size of heat treatment process.

Founded in 1999, Forever specializes in supplying induction heating equipment for steel bars, steel pipe heat treatment equipment and other induction heating and heat treatment furnaces. We have supplied nearly 3000 sets of induction heating and quenching equipment for nearly 1600 heat treatment enterprises since our establishment.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 10-13-2018