Induction heating furnace is one of the most popular metal heating equipment in the heat treatment market. By virtue of its special heating principle, environmental protection, energy saving and low carbon production can be realized in the production process. Let’s explore the advantages of induction heating equipment.

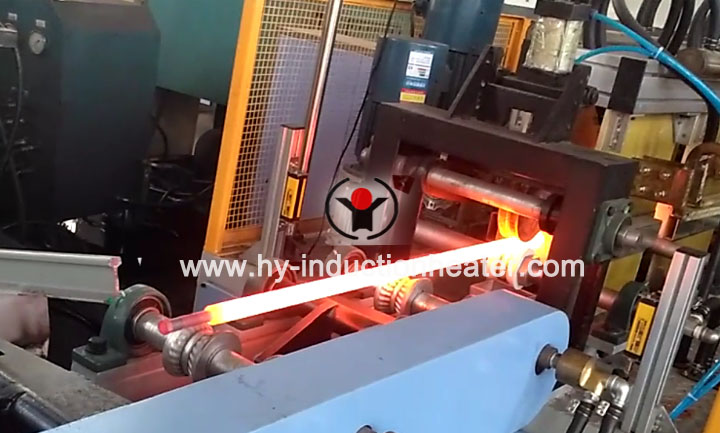

1. The maximum efficiency of induction heating is very fast and can greatly improve the production efficiency; the workpiece interior can produce heat directly and quickly (for example, it can reach more than 1000 ℃ in 1 second). Start up very quickly; do not require preheating or cooling. The induction heating process can be completed at the processing site near the cold rolling or hot rolling mill without having to send the workpiece in batches to the far-away heating furnace area or subcontractor.

2. The unique energy-saving process converts 90 percent of energy into effective heat, compared with about 45 percent for conventional reheating furnaces. And because induction heating does not require preheating and cooling beat, the standby heat loss can be minimized.

3. Induction heating in manufacturing and automation processes eliminates inconsistencies and quality problems associated with open fires, sprays, and other heating methods. After correct calibration and installation of the system, the error can be eliminated and the heating process is accurate and consistent. The use of intermediate frequency power supply can achieve accurate temperature control; and can instantly turn on or off the power supply. Through closed-circuit temperature control, advanced induction heating equipment can measure the temperature of different workpieces. Can set specific heating, constant temperature, and cooling speed, can record the data of each work piece.

4. The quality of the product is induction heating. The workpiece to be processed does not need direct contact with flame or other heating medium, but generates induction current inside the workpiece by alternating current. Therefore, can minimize the product hot deformation and waste rate. To improve the quality of the product, the workpiece is enclosed in an isolated container filled with inert or reductive gases in a vacuum environment to eliminate the effects of oxidation.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-07-2019