Forever has experienced senior engineers who have worked in the field of induction heating for many years. They have rich experience and practice in the design, process, manufacturing, and management of Steel bar induction heating equipments, focusing on providing customers with excellent solutions and services for steel rod induction heating furnaces and steel pipe heating equipment. Our medium frequency induction heating furnaces are sold to multiple countries, where you can enjoy our reliable service, stable and reliable product quality, and convenient transportation location!

The manufacturing process of the inductor for steel bar induction heating furnace is designed based on the process parameters provided by the user, with the ratio of the inner diameter of the inductor coil to the outer diameter of the billet being within a reasonable range. The sensor coil is made of a large cross-section T2 rectangular copper tube that is annealed, wound, acid washed, water pressure tested, baked, mica tape, and processed through multiple insulation, drying, knotting, assembly, and other main manufacturing processes. It is then fixed as a whole, and the entire sensor is made into a rectangular prism with good vibration resistance and integrity. The two ends of the sensor are protected by water-cooled furnace copper plates, which can effectively prevent electromagnetic radiation from causing harm to the operator. The equipment has a durable life of more than 5 years.

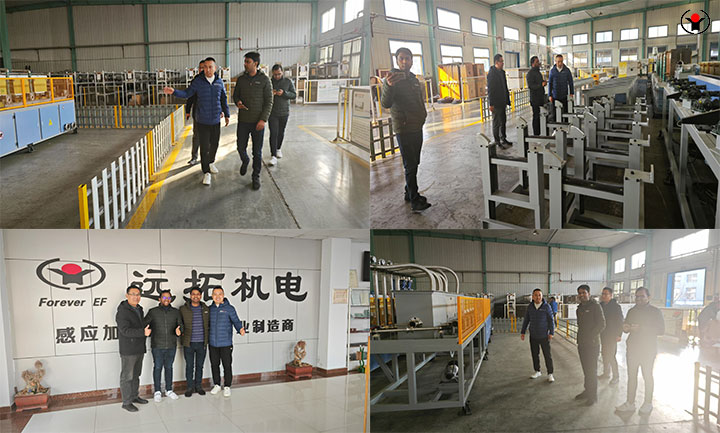

Hebei Forever Electromechanical carefully designs stable steel heat treatment equipment that meets customer requirements, striving for a win-win situation with customers.

(1) According to the actual needs of the customer, configure the power level of the steel bar heat treatment equipment,

(2) Design and manufacture according to customer needs, and provide customers with a stable and durable steel bar heat treatment equipment production line design process.

(3) Train relevant technical personnel for customers to master the operation process of steel bar heat treatment equipment.

(4) The company sends engineering and technical personnel to the user’s site to design processes and solutions for the user. And assign senior technical personnel to assist customers in designing and installing steel bar heat treatment equipment.

(5) During the sales process, the production process of the Steel bar induction heating system is constantly tracked. While ensuring the quality of the steel bar heat treatment equipment, the equipment is delivered to the user’s site within the contract signing date. Depending on the size of the equipment, the delivery time is generally between 20-60 days.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-13-2025