The collector on the inductor of the long bar induction heat treatment machine

Forever is located in Wuqiao, a famous acrobatic town in the world. It has high-end technical personnel in Hebei long bar induction heating equipment industry. Since its establishment, the company has strengthened cooperation and exchanges with many professional institutions in China and has advanced professional and technical standards in the field of induction heating.

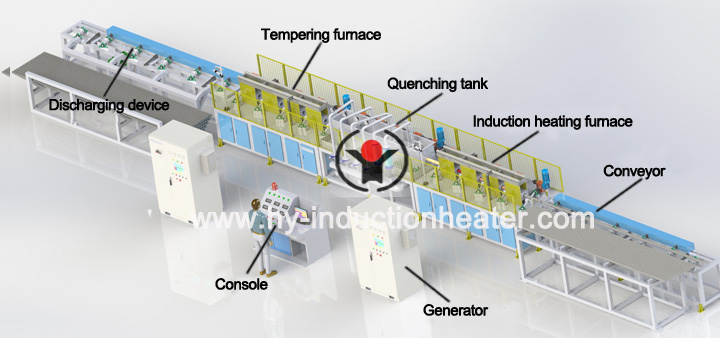

Inductor is an important part of the steel bar quenching furnace, and it is an important part of heat treatment for the workpiece. But do you know a collector on the inductor? If you are not familiar with this collector, then look at this article, I believe you will have a great harvest.

A collector, also known as a strong current, is a component mounted on the inductor. The relationship between it and inductor is similar to the relationship between primary winding of transformer and secondary winding. This shows how important it is to the inductor. Let’s look at the main functions of the collector.

1.It will be easier to put the inductor through collector.

1.It will be easier to put the inductor through collector.

The collector can be taken out or put into the inductor of the steel bar quenching furnace. The difficult problem of entering the inductor is solved for the parts which are difficult to enter the effective area, such as crankshaft and camshaft.

2. Can increase the local power density of the heating surface.

Because the local area is surrounded by the collector, the effective area is increased in length, so the power allocated to the local area is increased to achieve local flow collection and improve the power density.

3. Used for heating small parts on steel bar quenching furnace.

Because the heating area of the part is too small, the inductor is difficult to be designed into multi-turn, the use of collector can make the inductor obtain greater power and transfer to the part.

4.Adjustable hardened zone width.

The effective area between the collector and the inductor is positioned through the mica insulation, and the relative position between the two allows a small amount of adjustment. When the hardened area needs to be adjusted, it can be adjusted through the movement of the collector position.

Forever is specializing in research and production of induction heating and induction heat treatment furnace. In line with high-tech, high starting point, high quality principles, Forever strives to provide users with quality products. Forever products is widely used in petroleum industry, automobile industry, wind power industry, railway industry and other industries. Forever mainly uses IGBT and other new high-power devices with integrated, modular basic scientific and technological characteristics. Equipped with new output high frequency transformer, the power is greatly improved, and reliability is developed. This steel bar quenching furnace has the advantages of high heating efficiency, low failure rate, low power consumption and reliable protection.

We always adhere to the principle of “technology first, service first”, so that users can obtain high-quality products at satisfactory prices, and enjoy timely and thoughtful after-sales service.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 08-28-2018