Taiwan customers once again buy inline induction billet heater, 20 years of rich production experience for your customized production.

Recently, Forever sign one contract with one steel mill enterprise in Taiwan about 2500KW inline induction billet heater, which is our second customer in Taiwan for the similar project of inline induction billet heater.

The iron and steel Group is one of the well-known iron and steel processing and manufacturing enterprises in Taiwan. Its products have a high market share in north of Taiwan. Previously, the iron and Steel Group has come to visit our factory and then finally they decided to place the order with us after thinking over and over.For these projects, our factory has many cases ,which mainly produced for some state owned enterprises and large steel mill at abroad.

The order billet induction heating furnace is what we accepted under the situation of our production line is very busy at presnet. After arranging the order to the production department, the technician has finished the whole set of drawing design and confirmed all the components in one week and we gave great attention to this project.

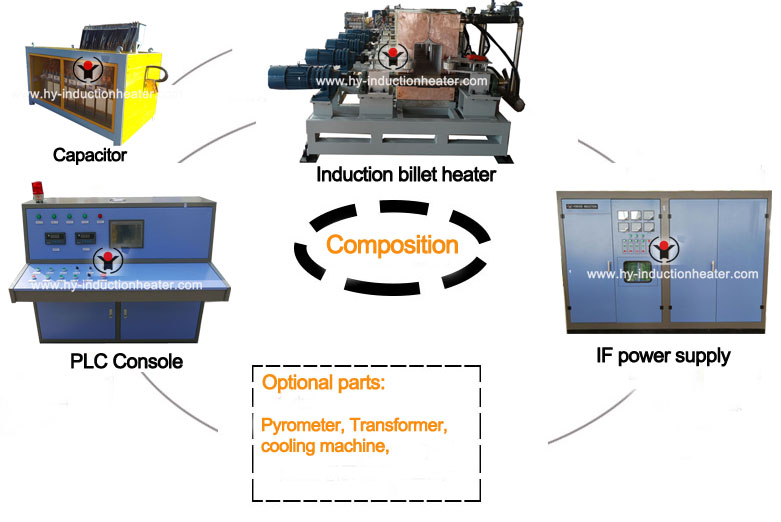

The steel billet induction heating furnace is strictly customized according to customer requirements, and a series of customizations are made on the functional structure.

1. In the PLC touch screen remote control console, we adopts man-machine interface for users to customize the production. Siemens 10-inch color touch screen interface is more friendly, programming is more intuitive; all-digital, high-depth adjustable parameters, so that users of steel billet induction heating furnace can control more handy.

2.Traceable process history curve, industrial computer system standard. Accurate to 0. 1 second recording accuracy, image and accurate temperature trend chart of billet heating furnace. Up to 1T capacity storage space, permanent storage of all billet heating process records for decades.

3. The conveying roller is driven by a special motor for frequency conversion and speed regulation. The motor speed is adjusted by a frequency converter to meet the requirements of different processes.

4. Multiple protection functions: overtemperature alarm and power off, water alarm and power off, temperature deviation alarm, SCR short-circuit alarm, program termination alarm and power off.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction hardening and tempering furnace is glad to be your partner in the field of induction heating.

Post time: 10-27-2018