induction heating equipment is the equipment for heating and treating metal workpieces through the principle of electromagnetic induction. Its main structure includes the following parts:

1. Power supply device

Function: Provide a stable medium or high frequency AC current.

Features: Power size and frequency can be adjusted to meet different process requirements.

2. Induction coil

Function: Through the induction current on the surface of the workpiece to achieve rapid heating.

Features: According to the shape and size of the workpiece design, the common shapes are spiral shape and ring.

3. Cooling system

Function: to cool the equipment and workpiece to prevent overheating and damage.

Features: Generally using water cooling or air cooling system, to ensure the continuous and stable operation of the equipment.

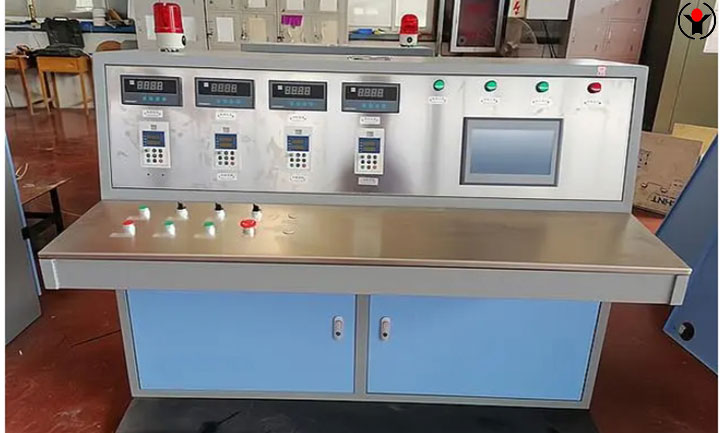

4. Control the system

Function: Control and adjust the operating state of the equipment, including power, frequency and heating time.

Features: Modern control systems are usually equipped with PLC (programmable logic controller) and HMI (man-machine interface), easy to operate, accurate control.

5. Workpiece transmission device

Action: automatically or manually place the piece in the induction coil and remove after heating.

Features: It can be manual placement, mechanical transmission or automatic assembly line system to improve production efficiency.

Induction heat treatment furnace is mainly composed of power supply device, induction coil, cooling system, control system and workpiece transmission device. All the parts cooperate with each other to achieve efficient and uniform metal heating treatment, which is widely used in various heat treatment processes.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 08-15-2024