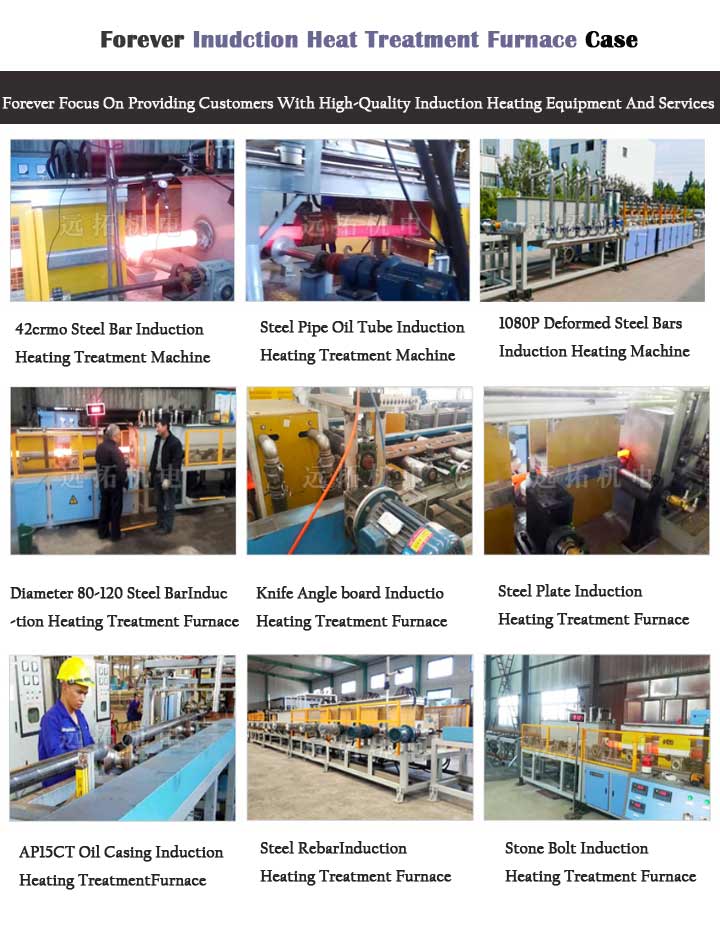

Forever Mechanical and Electrical specializes in producing steel pipe quenching production lines, which can adjust and treat round steel pipes with specifications ranging from 20 to 150 meters. The entire process of the steel pipe quenching production line is continuously transmitted by a continuous inclined roller track, and the steel rotates forward in a rotating manner, which can ensure the uniformity of steel heating and cooling and achieve better flatness.bar Induction heat treatment furnace

Composition of steel pipe quenching furnace:

1. Feeding mechanism

2. Conveyor roller table (with variable frequency roller device)

3. Quenching induction heating systembar Induction heat treatment furnace

4. Quenching spray system (including stainless steel spray ring, flow meter, and variable frequency idler)

5. Discharge mechanism Long bar quenching furnace

6. Medium frequency fire equipment PLC main control console (including control technology and signal isolation control board and programmer) Material of roller table: Cr25ni20 is used in the quenching section, 1Cr18ni9 is used in the tempering section, and GCr15 is used in the other sections. Operating table: stainless steel material is used.

Forever Mechanical and Electrical specializes in the production of steel pipe quenching furnaces, which can adjust and treat round steel pipes with specifications ranging from 20 to 15 meters. The entire process of the steel pipe quenching furnace is carried out by a continuous inclined channel for single continuous transmission, and the steel rotates forward in a rotating manner, which can ensure the uniformity of steel heating and cooling and obtain better flatness.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 08-25-2023