At present, there are mainly induction heating equipment, continuous furnaces, and salt bath furnaces on the market. These three devices can all be used for quenching rectangular pipes, improving the strength, hardness, and wear resistance of seamless steel pipes.

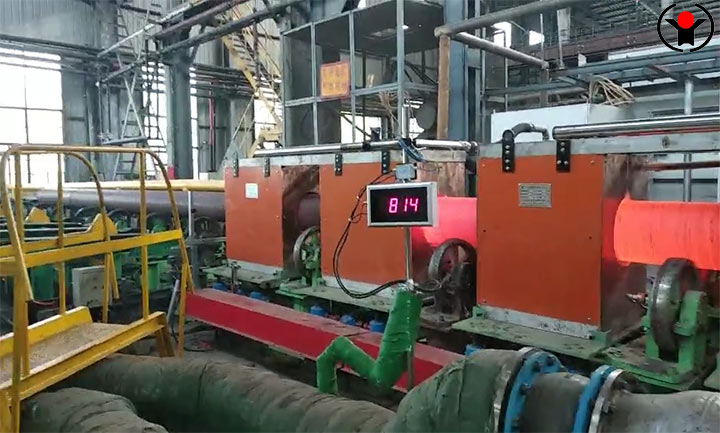

The steel pipe induction heating equipment adopts the principle of electromagnetic induction, which generates eddy currents inside the steel pipe to achieve fast heating speed, uniform heating, and easy control. It is suitable for heat treatment processes such as heating and quenching of large diameter steel pipes, but needs to be customized according to parameters such as pipe diameter, length, and production efficiency.

Continuous furnaces are suitable for large-scale continuous production, with controllable heating and cooling processes. They are often used in heat treatment processes such as annealing and normalizing. However, they are not economical for small-scale production, and equipment adjustment and maintenance are complex.

Salt bath furnace is a traditional quenching equipment that heats uniformly and is suitable for steel pipes of various shapes. But cleaning and maintenance costs are high, and there are environmental and safety hazards.

Taking into account multiple factors such as cost, efficiency, and environmental protection, for the heat treatment of 95-120mm diameter steel pipes, Yuantuo professional technical engineers recommend the use of Steel pipe heat treatment equipment . Induction heating equipment not only has the advantages of high efficiency, energy conservation, and environmental protection, but also can accurately control the heating area and temperature, ensuring the uniformity and consistency of quenching effect.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-18-2024