Steel pipe induction annealing equipment is an industrial equipment specifically used for steel pipe heat treatment. Its main function is to improve the microstructure of steel pipes through heating, insulation, and slow cooling processes, thereby enhancing their mechanical properties. Annealing treatment can eliminate internal structural defects in steel, homogenize chemical composition, refine grains, reduce residual stress, lower hardness, improve plasticity and toughness, and enhance cutting performance. These changes are crucial for ensuring the performance of steel pipes in subsequent processing and use.

The working principle of a steel Pipeline induction annealing equipment is based on heating the steel pipe to an appropriate temperature, usually the temperature at which the steel undergoes phase transformation or partial phase transformation, and then slowly cooling it after a period of insulation. This process helps to achieve the microstructure improvement mentioned above. The design of an annealing furnace may include methods such as resistance heating and gas combustion heating, and is usually equipped with intelligent temperature control instruments and automatic control systems to ensure the accuracy and repeatability of the heating process.

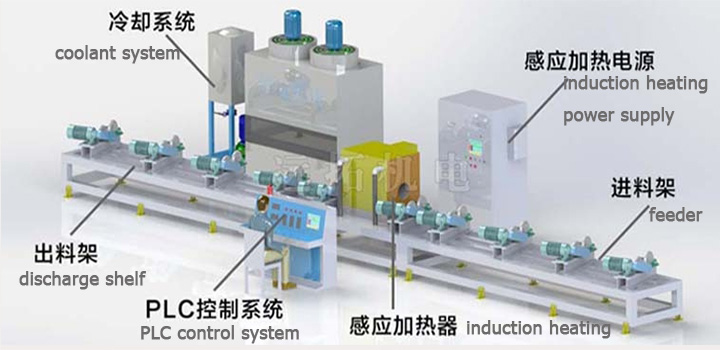

The design of the Steel pipe annealing equipment takes into account high efficiency and product quality. For example, some annealing furnaces use roller bottom transport systems, which allow steel pipes to move continuously during the heating process, avoiding uneven heating and potential damage caused by fixed contact points. In addition, modern annealing furnaces may include high-speed jet cooling systems, special high-temperature resistant bearings, electrical automatic control systems, and programmable logic controllers (PLCs), all of which are designed to improve production efficiency, ensure product quality, and simplify the operating process.

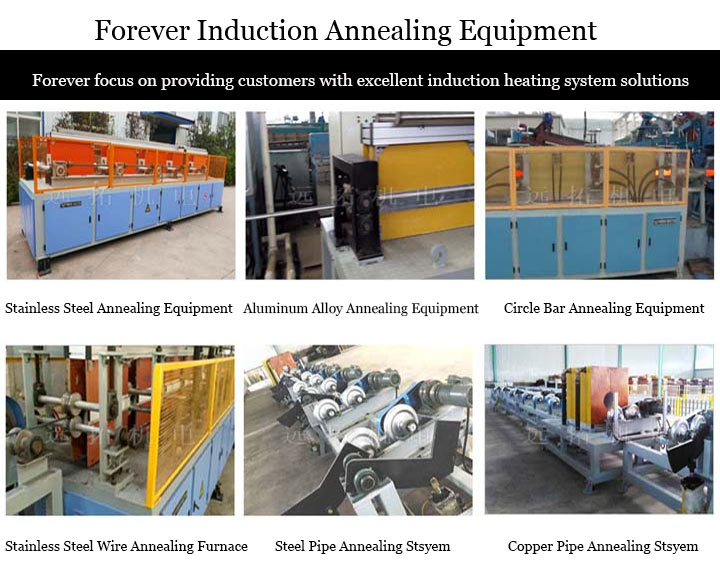

Steel pipe annealing furnaces are widely used for heat treatment of metal materials such as steel pipes, stainless steel pipes, alloy steel pipes, copper pipes, and copper materials, especially in applications that require bright surfaces and uniform hardness.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 10-10-2024