FOREVER electromechanical specialty provides billet secondary heating furnace. The company gathers a number of senior technical engineers engaged in induction heating equipment industry and heat treatment industry to form a high-tech enterprise integrating the research and development, design, production, sales and service of billet secondary heating, billet temperature raising and temperature supplement equipment. It has always been operating in ISO9002 quality management system certification, CE quality certification and a number of invention patents.

Process parameters and requirements of steel billet induction reheating furnace:

1. Equipment brand: FOREVER Electromechanical

2. Equipment name: steel billet induction reheating furnace

3. Steel type and material: Q235q, Q345q, Q245R, A32, D32, A36, D36, etc

4. Billet size range: (6mm × 6mm)-(500mm × 500mm)

5. Billet length range: more than 2m

6. Large bending degree of steel billet before entering the furnace: there are different degrees of bending degree according to different steel grades. What should we do if the bending degree of the billet is greater than 3mm/m before it is fed into the electric furnace? The steel billet reheating equipment designed by us can meet your requirements by adjusting the size of the inductor according to the bending degree of your steel grade.

7. The temperature before the billet surface is put into the furnace and the billet outlet temperature: we design and produce according to the effect that users need to achieve.

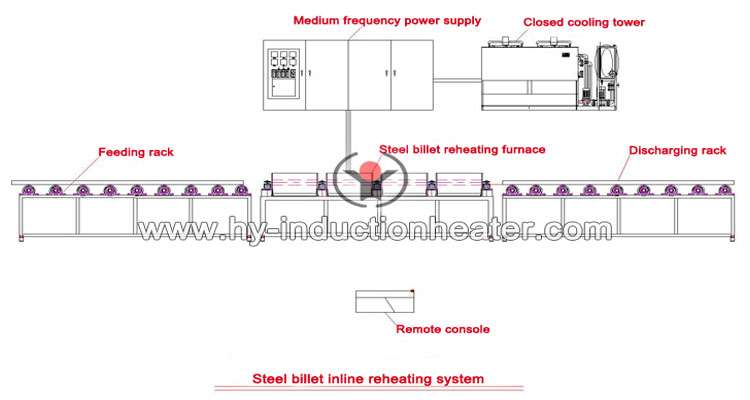

8. Control system: The whole heating process is automatically controlled by PLC, and the production records such as heating quantity are displayed at the right time. This console is used separately, with a specially customized human-computer interface, highly user-friendly operation instructions, all digital, highly adjustable parameters, and a one button restore function, which is simple to operate.

9. Feeding and guidance system: each axis is driven by an independent motor reducer, and multi axis drive is set. A single frequency converter is used to control the synchronization of multi axis operation. The components are selected from famous brands, with reliable quality and stable operation. 304 non-magnetic stainless steel guide wheel is used to keep the axial direction of the guide wheel moderately elastic to adapt to the bending of the billet within the allowable range.

10. Closed loop temperature control. The closed loop control system is composed of the American Leitai infrared thermometer and the German Siemens S7. The power of the power supply is automatically adjusted according to the initial temperature of the billet entering the induction heater and the feed speed, so that the heating temperature remains constant before the furnace is discharged and the workpiece is heated evenly.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 11-21-2022