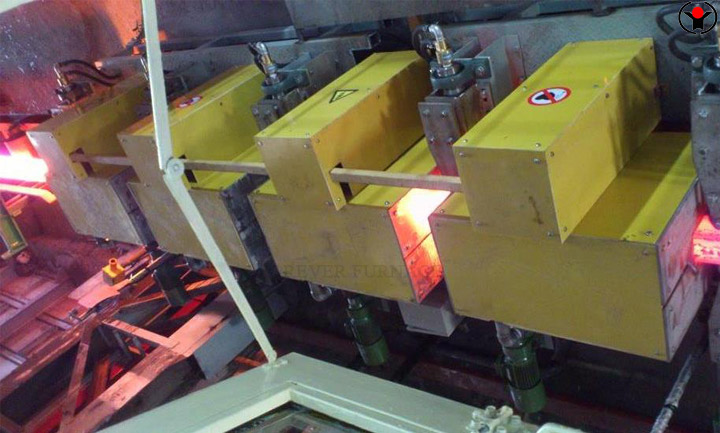

This set of steel billet induction heating equipment has the application of DT in the steel ball rolling production line. The billet is first heated from room temperature to around 800 degrees in a gas furnace, and then raised to around 1000 degrees by induction heating. This segmented heating mode effectively avoids the problem of damage caused by high temperature heating in gas furnaces. Transfer the high-temperature area to the induction heating area, with a simple layout and a separate furnace body design that makes maintenance more convenient and rapid.

However, this steel billet induction heating furnace has very high requirements for the design of sensors, not only to accurately reach the specified temperature, but also to ensure that the steel billet is uniformly heated and burned through both inside and outside. This requires precise consideration and optimization in terms of sensor power, frequency, coil design, and other aspects. Only in this way can the advantages of efficient, accurate, and uniform induction heating be fully utilized, meeting the strict requirements of steel ball rolling technology for billet heating, and improving product quality and production efficiency.

Hebei Yuantuo Electromechanical is the source factory of steel billet induction heating production line . Welcome to inquire by phone.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-27-2024