At present, steel ball manufacturing mainly focuses on rolling steel balls, but for steel balls with a diameter exceeding 120mm, a Steel ball forging induction heating machine is required for production, which is commonly known as small steel ball rolling and large steel ball forging. The use of air hammer forging makes the internal structure of ball milled steel balls denser, improves toughness and density, enhances wear resistance, reduces breakage rate, and maintains excellent stability in various harsh environments.

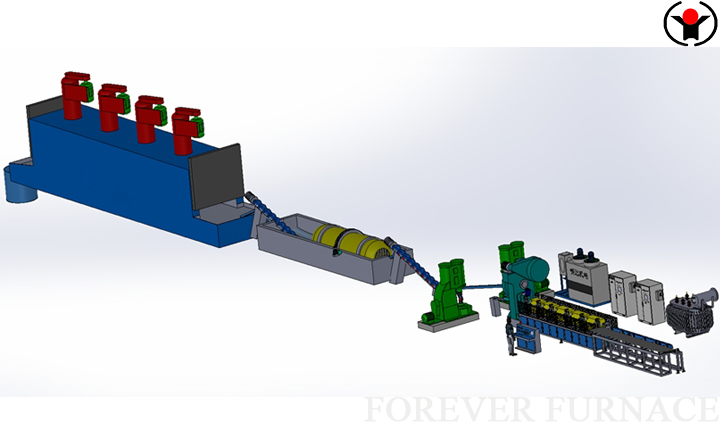

The characteristics of the Forever steel ball forging production line mainly include the following aspects:

Efficient production

The Forever Forging steel ball production line adopts advanced automated feeding technology and uses medium frequency induction furnace heating to quickly and uniformly heat round steel, with low skin fire consumption. During the operation of the equipment, rolling forging is carried out under continuous compression of two spiral rolling distances, and 70 to 80 high-quality steel balls can be produced per minute.

Fully automatic intelligent control

This production line has fully automatic intelligent control function, which can achieve the entire production process of automatic feeding, heating, rolling, and ball discharge through PLC remote intelligent control. This intelligent control system can greatly reduce manual intervention, improve production efficiency and product quality.

Wide applicability

The Forever steel ball forging production line is suitable for the production of steel balls rolled from bar materials with diameters ranging from 100mm to 125mm. Compared with the traditional air hammer forging steel ball production method, its production efficiency has been increased by 30 times. The steel balls produced by the Forever Steel Ball Forging Production Line have high hardness, wear resistance, and impact toughness, which can meet the production needs of different customers.

Environmental protection and energy conservation

The Forever steel ball forging production line adopts the principle of electromagnetic induction heating, which cuts metal through magnetic lines and generates eddy currents inside the bar material to quickly achieve uniform heating. This non-contact heating method not only has higher heating efficiency compared to traditional fuel heating methods such as coal, gas, and oil, but also has the advantages of environmental protection and energy conservation.

In summary, the Forever steel ball forging production line has the characteristics of efficient production, fully automatic intelligent control, wide applicability, high-quality products, and environmental protection and energy saving. It can meet the needs of modern industry for fast and environmentally friendly heating, improve production efficiency and product quality.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 01-09-2025