Recommend reading ! The really good steel bar quenching furnace is coming !

Steel bar quenching furnace, also known as steel quenching furnace, is a common quenching equipment in the whole steel quenching production line. The steel bar quenching furnace mainly uses two kinds of heating and heat treatment principles of “induction heating” and “induction quenching” to combine each other, and then makes the steel bar after heat treatment become beautiful in appearance, reasonable in physical and chemical properties. All can meet the rigorous production process requirements, the current application in the iron and steel processing industry is very popular, the following is about characteristics of steel bar induction heat treatment furnace:

Steel bar quenching furnace technology:

Heat treatment and quenching process is a kind of hot-working process that changes the structure, performance and internal stress state of bar material by heating and quenching cooling. It is a kind of hot-working process that improves the performance of products in the machinery manufacturing industry, and cooling with a certain quenching and cooling process and speed after using, that is, through heating speed, cooling speed and temperature. The organic coordination of this link makes the internal structure of guide wheel material or other steel change, so as to achieve the process method of improving the performance of steel material.

Under normal circumstances, the quenching process generally includes heating, quenching, cooling three steps. Firstly, the steel material is driven and heated by the drive roller system and the induction heating furnace; then it is heated to 1000 °C by the induction heating furnace quickly and then transferred to the quenching water tank for spray quenching; finally, the material of the steel bar is transferred to the cooling part by the roller drive, thus forming a form of production line to protect it. The performance requirement of the steel bar is verified.

Advantages of selecting steel bar quenching furnace

1. Steel bar quenching furnace quenching product shape is good: It is used for bar material heating and quenching heat treatment production, play a role in optimizing and strengthening the physical and chemical properties of steel bar, so that the material internal stress elimination without quenching cracks, deformation, cracking and so on.

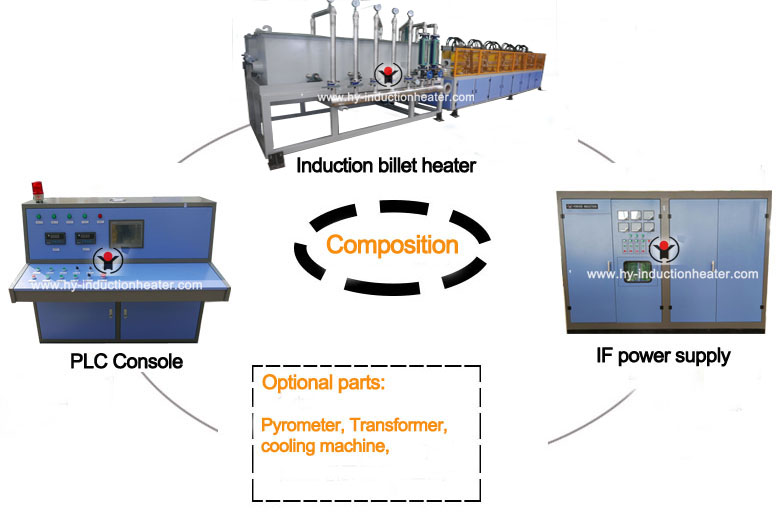

2. The production efficiency of steel bar quenching furnace is higher: the equipment is equipped with 100 cubic meters/h closed cooler and PLC intelligent automatic control and monitoring system, power cabinet and induction furnace are composed of pure water internal circulation, external circulation for tap water spraying, air to take away the heat generated by internal circulation, timely monitoring of heating temperature, current, furnace temperature, quenching temperature and other functions.

3. Higher temperature vigilance: Set up one pyrometer at the outlet of the inductor of long bar heat treatment machine and display in the PLC console, which will take part in the closed-loop temperature control.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 10-06-2018