Quenching and tempering process of 42CrMo steel wind electric bearing ring

Oil is often used as quenching and tempering medium for 42CrMo steel bearing rings. The impact energy of quenched and tempered bearing rings is low due to the limitation of cooling performance of oil. The special service conditions of 42CrMo steel wind bearing rings are very strict for impact work. In order to meet the technical requirements of 42CrMo steel wind power bearing ring, it is necessary to test the quenching and tempering technology of 42CrMo steel wind power bearing ring.

1. Process test

(1) Test ring

42CrMo steel wind bearing rings are chosen as test rings. The size of the test ring is Φ700mm×Φ450mm×180mm (OD×ID×Height). The chemical composition of the test ring is shown in Table 1. The chemical composition conforms to GB / T 3077 – 1999.

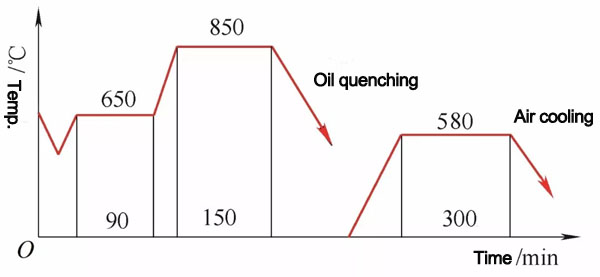

Table 1 Chemical composition (mass fraction) of test rings (%)

(2) Test process

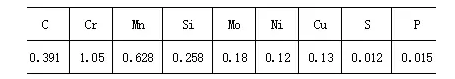

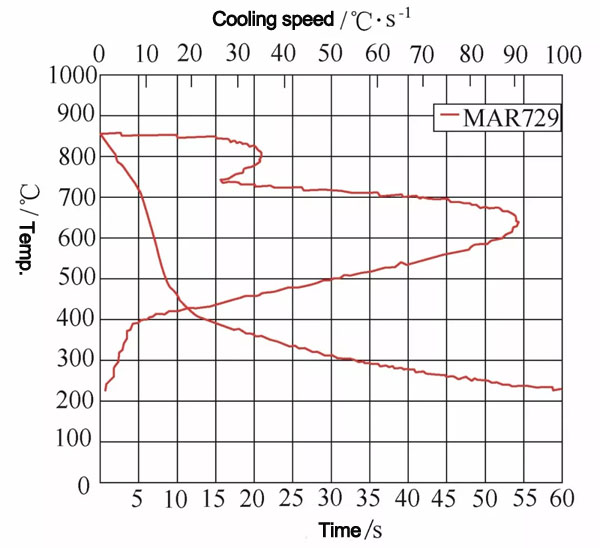

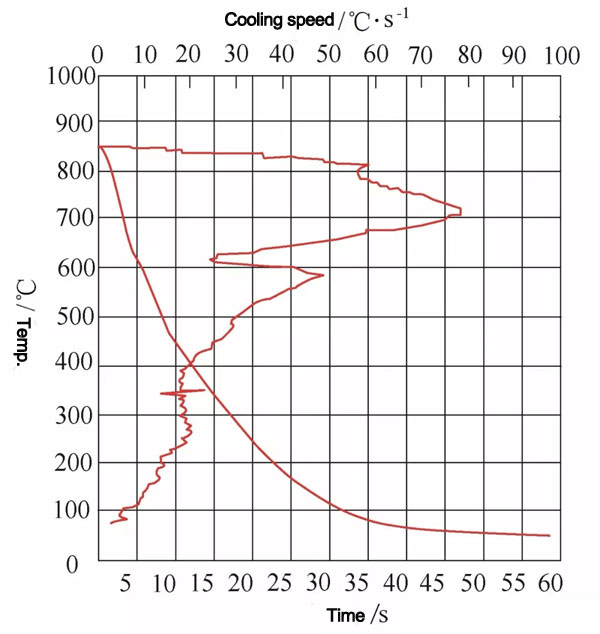

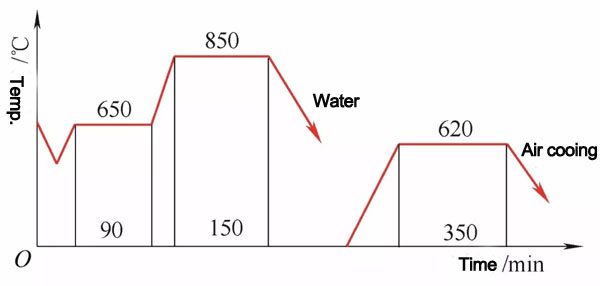

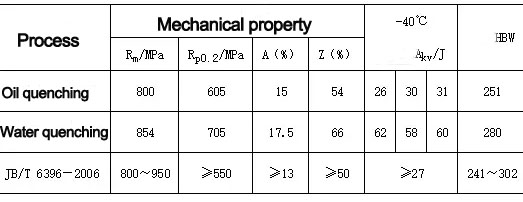

Quenched and tempered 42CrMo steel bearing rings were quenched and tempered with oil and water quenching medium respectively. The cooling performance curve of oil quenching medium is shown in Fig. 1, the cooling performance curve of water quenching medium is shown in Fig. 2, and the process curve of oil quenching and tempering is shown in Fig.3.and the process curve of water quenching and tempering is shown in Fig.4.

Figure 1 Cooling performance curve of oil

Figure 2 Cooling performance curve of water agent

Figure 3 Curve of quenching and tempering process for oil quenching

Figure 4 Quenching and tempering process curve of water agent

(3) The mechanical properties of the test ring after quenching and tempering

According to the quenching and tempering process of Fig. 3 and Fig. 4, 42CrMo steel wind power bearing rings are quenched and tempered, and the mechanical properties of the samples are tested. The test results are shown in Table 2.

Table 2 Test results of mechanical properties

It can be seen from table 2 that the mechanical properties of the 42CrMo steel bearing ring can not meet the technical requirements after quenching and tempering with oil quenching medium, and the mechanical properties of the bearing rings can meet the requirements of the 42CrMo steel wind electric bearing rings after the quenching and tempering with water quenching medium.

2. Results analysis

From Figure 1 and Figure 2, it can be seen that the high temperature cooling rate of the oil quenching medium is too small, which leads to the shallow hardened layer of the bearing ring and the few martensite after quenching; and the high temperature cooling rate of the water quench medium is faster than the oil, and the hardened layer depth of the bearing ring and the number of martensite after the quenching after quenching are more than that of the oil quenching medium. The amount of martensite after quenching directly determines the amount of sorbite after high temperature tempering, and the number of sorbite determines the ultimate mechanical properties of bearing rings.

The cooling performance of water quench medium at low temperature is equal to that of oil quenching medium, so the bearing ring which is quenched and tempered by water quenching and tempering technology will not produce cracks.

3. Conclusion

(1) The mechanical properties of 42CrMo steel wind power bearing rings quenched and tempered by water can meet the requirements of 42CrMo steel wind power bearing rings.

(2) After water quenching quenching and tempering, the 42CrMo steel wind bearing bearing rings can ensure that no quenching cracks are produced.

This article is from Forever company-continuous quenching and tempering furnace manufacturer

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of long bar heat treatment machine is glad to be your partner in the field of induction heating.

Post time: 08-02-2018