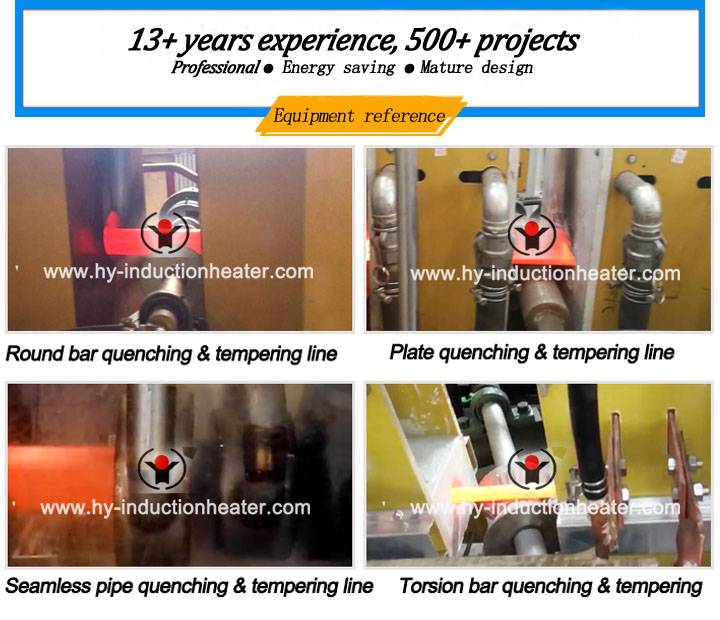

Production of pipe hardening and tempering furnace, customized production line proposal

Steel pipe, divided into stainless steel pipe, seamless steel pipe, thick wall steel pipe and other different types, is widely used in oil transportation, engineering structure, mechanical manufacturing, geological drilling, high pressure equipment and petrochemical and thermal equipment. The demand of steel pipe is large, the application field is more, but the performance requirements of steel pipe are high. So hardening and tempering process is an essential procedure for steel pipe, which is the most important for steel pipe performance. Yuantuo mature pipe hardening and tempering furnace has played an important role in improving the pipe performance including tensile strength, yield strength. As per customer process requirement, the pipe after heat treatment with our hardening and tempering furnace can reach L80, P110 or higher API standard.

Complete set of equipment for pipe hardening and tempering furnace

“It is necessary to have effective tools to do good work”. So before achieving steel pipe higher value, the customer should need a set of steel pipe hardening and tempering furnace with good quality and better performance. Usually, the a set of pipe hardening and tempering furnace has included the follwing parts:

1.Medium frequency power supply-the main component of the induction heating equipment. Its structure is simple, the power is large, the workpiece is heated even and is less damaged. It is the most suitable to be used for pipe heat treatment process.

2.Induction heating system- the main part of the pipe hardening and tempering furnace. It is different from the simple induction coils only. The production course is the worker make the copper tube induction coils first and then pour the Korea import refractory cement. Then the insulation plate will be covered outside of the induction heating coils. This method can reduce the heat loss and safer for the workers.

3.Conveying system-used to transport the pipe during the pipe heat treat process. Its structure design is more unique and has the characteristics of low cost, high transport rate, high elevation, smooth operation and long service life.

4.Control system: the steel pipe hardening and tempering furnace uses PLC and industrial control machine to control the whole set of equipment. It can ensure that the workpiece is heated evenly and efficiently in the induction heat treating furnace. At the same time, the equipment itself has the advantages of low noise.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.

Post time: 05-18-2018