The process of Forever steel billet induction reheating machine mainly includes the following:

Cold billet heating process

Process flow: Heat the billet from room temperature to 1200 ℃ to provide the required high temperature environment for subsequent rolling.

Application scenario: Suitable for situations where steel billets need to be directly heated at room temperature, it can effectively improve the plasticity of steel billets and provide ideal temperature conditions for subsequent processes.

Online heating process for steel billets

Process flow: After the continuous casting machine discharges the billet, in order to avoid heat loss due to cooling of the billet, the Forever billet heating electric furnace rapidly heats the billet to reach the rolling temperature.

Application scenario: This process can efficiently recover the remaining heat of the steel billet, ensuring that the billet maintains the ideal temperature before rolling. Online heating not only helps save energy, but also improves the internal structure of steel billets and enhances material properties.

Induction heating technology

Principle: Adopting induction heating technology, steel billet induction reheating furnace has the characteristics of fast heating speed, high efficiency, energy conservation and environmental protection. It can quickly penetrate the steel billet material and uniformly heat it, avoiding the overheating or uneven phenomenon that occurs in traditional heating methods.

Advantages: It has non-contact and high energy efficiency characteristics, especially suitable for large-scale steel billet heating processes, and has obvious economic advantages.

Equipment composition and characteristics

PLC main control system: equipped with high-performance Siemens PLC control system, it can achieve full intelligent control of the heating process. It has good stability and flexibility, and can adjust the heating power flexibly according to production needs to ensure that the temperature of the steel billet after being discharged meets the process requirements. It also has real-time monitoring and fault self diagnosis functions, which help improve production efficiency, reduce downtime, and ensure the long-term stable operation of equipment.

High precision infrared temperature measurement technology: using the American Raytheon infrared thermometer, it can detect the surface temperature of the steel billet in real time and feed the data back to the PLC control system. The system automatically adjusts the heating power based on the temperature measurement data to ensure that the steel billet maintains a uniform temperature distribution throughout the steel billet induction heating equipment heating process.

Diversified applicability: Suitable for steel billets of different shapes, including round billets, square billets, tube billets, etc., to meet various production needs.

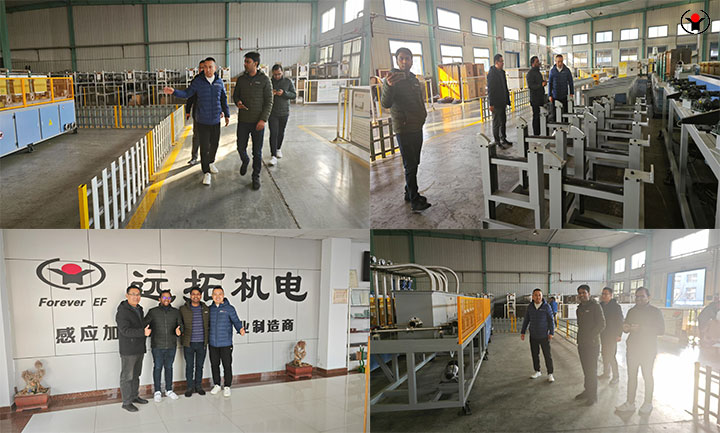

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-29-2025