Hardening and tempering equipment is an important part of steel bar heat treatment. Today, we will reveal its equipment principle and parameters.

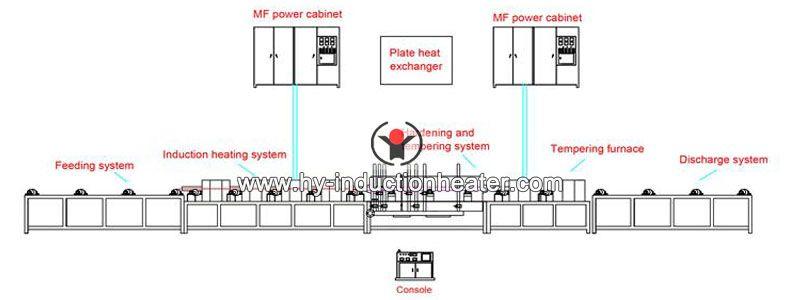

Hardening and tempering equipment is mainly used for long bar induction hardening and tempering machine. By controlling process parameters such as heating, cooling, and insulation, the steel bars can achieve the required mechanical properties and microstructure. The specific equipment principle is as follows:

1. Heating: Place the steel rod in a heating furnace and heat it to the required quenching or tempering temperature through methods such as resistance heating or induction heating. During the heating process, it is necessary to control the heating rate and temperature uniformity to avoid deformation or cracks caused by excessive temperature gradients.

2. Cooling: After heating to the required temperature, the steel rod needs to be rapidly cooled to transform its structure into martensite. The cooling method can be water cooling, oil cooling, or air cooling, depending on the steel grade and requirements. The cooling process requires controlling the cooling rate to ensure that the steel rod achieves the required hardness and microstructure.

3. Insulation: After quenching, the hardness of the steel rod may be too high and needs to be quenched and tempered. Usually, the steel rod is placed in a constant temperature furnace and kept at a certain temperature for a period of time to achieve stability of the organizational structure and adjustment of hardness.

Long bar induction heat treatment furnace equipment parameters:

1. Heating temperature: Set the temperature range to be heated according to the material and process requirements of the steel rod, usually in degrees Celsius (℃).

2. Cooling medium: The cooling method can be water, oil, or gas, and appropriate cooling medium can be selected based on the properties of the steel rod and product requirements.

3. Cooling rate: Control the cooling rate to achieve the required quenching effect, usually expressed in terms of temperature change rate (℃/s) or cooling time.

4. Tempering temperature: The insulation temperature during the tempering process depends on the material and hardness requirements of the steel rod, and is measured in degrees Celsius (℃).

5. Insulation time: The time required to maintain the steel rod at the quenching and tempering temperature to ensure the stability of the organizational structure and the adjustment of hardness, usually measured in minutes or hours.

It should be noted that specific equipment parameters may vary depending on factors such as steel bar material, size, strength requirements, and process standards. When quenching and tempering steel bars, appropriate parameters should be set according to the specific situation, and each link should be strictly controlled to ensure the ideal heat treatment effect.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 10-13-2023