The Steel pipe induction annealing equipment developed and produced by Hebei Forever Electromechanical Manufacturer uses new power supply and control system technology, making the steel pipee continuous annealing furnace efficient, energy-saving, and easy to operate. During the production process of the steel pipe continuous annealing furnace, we, Forever Electromechanical Manufacturer, strictly control every step to ensure the quality of the induction heating equipment. Forever Manufacturer is trustworthy!

Forever Pipeline induction annealing production line is an equipment used for steel pipe heat treatment. It is mainly used to heat the steel tube to a certain temperature and maintain it for a period of time, then slowly cool it to eliminate structural defects, improve the structure, homogenize the composition, refine the grain size, enhance the mechanical properties of the steel, reduce residual stress, and reduce hardness, improve plasticity and toughness, and improve cutting performance.

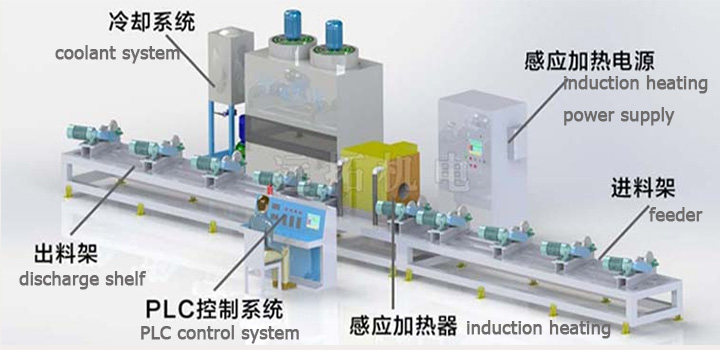

Working principle of steel pipe induction annealing furnace:

The steel pipe is fed into the furnace and maintained in continuity through a conveyor belt or roller system.

Heated to the required annealing temperature in the furnace, the heating method depends on the furnace type and steel pipe material.

After reaching the annealing temperature, the steel pipe stays in the insulation area for a period of time to ensure the appropriate insulation time is achieved.

Finally, the steel pipe is cooled by the cooling system outside the furnace to complete the annealing process. Throughout the process, different annealing treatments for steel pipes can be achieved by controlling parameters such as heating temperature, holding time, and cooling rate.

Characteristics of Stainless steel pipe induction annealing equipment

Uniform temperature: The furnace is equipped with a powerful stirring fan, and the electric heating elements are arranged reasonably. The temperature and atmosphere inside the furnace are evenly distributed, resulting in high-quality products.

Efficient production: The transmission adopts roller synchronous transmission, variable frequency speed regulation, smooth and reliable, suitable for bright heat treatment in non-ferrous metal industry, copper industry and other industries.

Environmental protection and energy saving: high degree of automation, no environmental pollution, smooth surface of processed parts, uniform hardness without oxidation.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-05-2024