During the use of Long bar induction quenching furnace , operational standards and process adjustments directly affect production efficiency and product quality. The following are answers to frequently asked questions by customers:

1. What should be checked before starting the steel bar induction hardening equipment ?

·Answer: Before operating the equipment, the following items need to be checked:

1) Whether the cooling water system is normal, and whether the water flow and pressure meet the requirements;

2) Is the connection of the induction coil secure;

3) Whether the PLC process parameter settings are consistent with the processing requirements;

4) Ensure that the surface of the steel rod is free of oil stains or foreign objects to avoid affecting the heating effect.

2. How to ensure the uniformity of heating temperature?

·Answer: The equipment is equipped with a multi-point temperature control system, which adjusts the power output in real time to ensure synchronous heating of the steel rod surface and core. At the same time, regularly clean the induction coil to maintain a stable magnetic field and avoid temperature differences caused by impurities.

3. What quenching methods does the equipment support?

·Answer: The steel bar induction hardening machine supports various processes such as rapid quenching and graded quenching. The specific selection can be adjusted according to the depth of the hardened layer and the performance requirements of the steel bar.

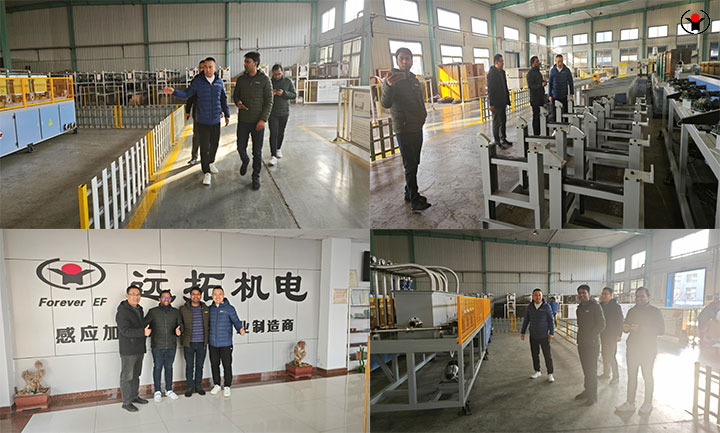

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 02-19-2025