FOREVER Mechanical and Electrical equipment Manufacturing Co., Ltd is a professional manufacturer of induction electric furnace and intermediate frequency Induction heating furnace

Nowadays, saving resources is our country’s basic national policy, saving energy, improving energy utilization efficiency, protecting and improving the environment. To promote the overall coordinated and sustainable development of the economy and society, induction electric furnace is a strategic task at present in our country. We should vigorously eliminate backward processes, equipment and technologies that have high energy consumption and pollute the environment, speed up the development of energy-saving technologies, and vigorously popularize them. Application of energy-saving, environmental protection of new processes, new equipment, new technologies and new products, but also to make full use of residual heat pressure.

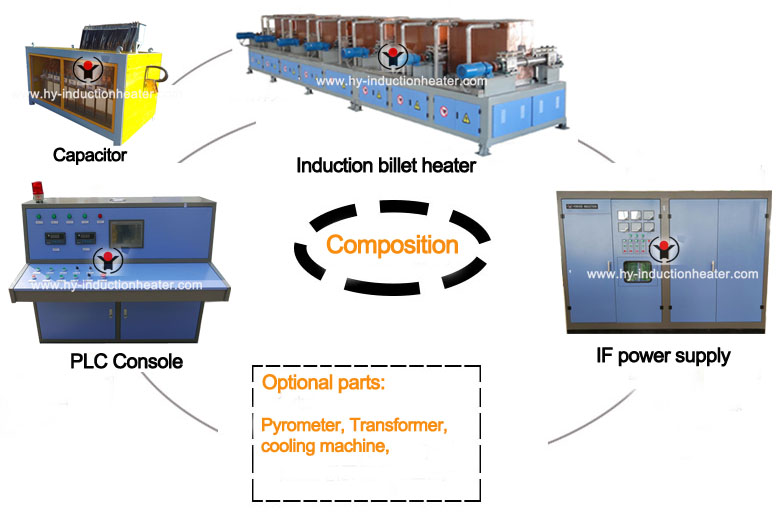

The remote electromechanical induction electric furnace has the advantages of high heating speed, can increase the productivity of heating equipment, and can form a continuous production line with other process equipment. For example, the bar goes into the forging press after induction electric furnace to press the workpiece, the workpiece has the uniformity of heating, and the qualified rate of the finished product after forging is high. The induction furnace is controlled by water cooled intermediate frequency power supply, which can realize high power regulation. The medium frequency power supply is equipped with various protection functions and fault alarm functions, which makes the induction furnace easy to operate and easy to maintain and check. In terms of electric heating of production equipment, the resistance furnace must be heated very rarely before the billet is hot-formed, because the heating temperature of the blank is relatively high and is limited by the electric heating element, so it is mainly heated by induction heating. Induction heating blanks have been used in forging, hot stamping, hot extrusion and hot shear cutting of blanks before hot forming. High efficiency induction furnace, according to your production requirements, you can be configured with high-performance control systems, such as touch screen control system, one-click start, the production of the entire set of induction heating equipment need only one person to guard, high efficiency, Cost of energy saving.

For 20 years only in the familiar field of induction heating equipment, we provide you with a suitable induction electric furnace, we have a perfect after-sales service group, induction heating furnace failure, you can contact our after-sale personnel at any time, Response within 2 hours, 24 hours to ensure the normal operation of your equipment, do not delay your production. If you have the demand of induction furnace, you can contact the technical staff at any time and serve you wholeheartedly.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-26-2019